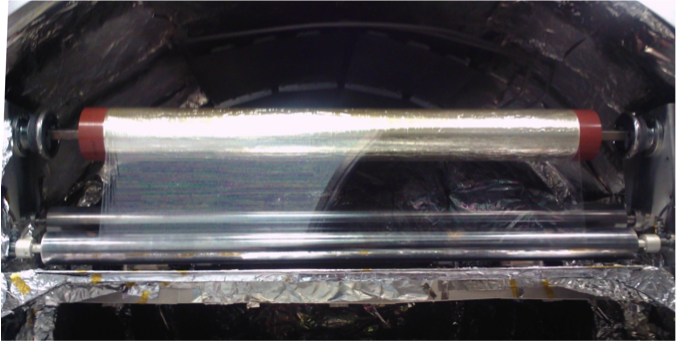

Innovative roll-to-roll coating process

Our unique roll-to-roll coating process was developed in-house for Electron Beam, Jori Source and Ion Assisted Deposition (IAD) of metallic and dielectric films (all processes scalable). 1.8m and 5m chambers accommodate a variety of applications, with deposition on film up to 1000m x 1.5m wide and a great deal of experience handling sub-10 µm films. Substrates move across four banks of e-beam guns, allowing up to four discrete layers per pass, and PID programmed rate monitoring allows for precise thickness deposition. Capability to process roll to roll film in a Rewinder cleanroom room (ISO class 5).

| Coating Technology | Applications | Technology Status |

|---|---|---|

| Multisource E-beam Evaporation | Reflective & Transmissive coatings: optical, IR, RF | Industry standard |

| Crystal Rate Monitoring for high volume production | Allow crystals to be changed automatically. Dual head with up to 48 crystals per e-beam source. | Proprietary (SBIR data rights) |

| Ion Assisted Deposition | Layer stacking of higher density material (crystalline), index control, durability | Industry standard |

| Jori Source deposition for dielectric layers | Mechanical protection, stress and emissivity management, low temp-hi rate deposition | Industry standard |

| Reflective coatings | Tailored thermal control properties | Designated supplier in ISiS specs |

| Low temperature coating of polymer substrates | Polyimide web | Proprietary (SBIR data rights) |