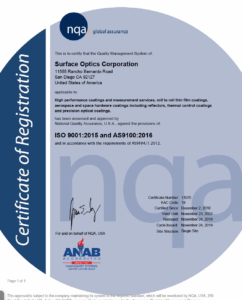

Certification

Surface Optics Corporation’s coatings lab is ISO Certified (AS9100 Rev D) with a a 2,000 sq.ft. cleanroom (ISO Class 7) primary lab utilizing 60 Hepa filters and a portable cleanroom housing roll-to-roll film Re-Winder (Class 5). Our quality system has been fully documented and implemented and is maintained as needed to meet the requirements of our Company vision and governing policies. Surface Optics has adopted a process-oriented method of management. This approach emphasizes the importance of continuous improvement and understanding, meeting and integrating the requirements of our customers, regulators, employees, suppliers, and shareholders.

Operations and Maintenance

- All operations Work Instruction and Checklist driven (Quality compliance, Procedural stability, Technician training and certification)

- Detailed Work Orders

- Processes Traveler Controlled

- AS9100 standard for preventative and incidental maintenance (Preventative Maintenance Program, Maintenance Action Program/Documentation, Coating Discrepancy Database)

Technician Training

Fifteen point in-house technical training program for Operator Certification:

- Coating Systems

- Production Safety

- Clean Room Procedures

- Power Lifter Certification

- Chamber Cleaning

- Chamber Re-Foiling

- Ebeam Guns

- Jori Sources

- Control Station Procedures

- 5 M Chamber Operations

- 1.8 M Chamber Operations

- Work Orders and Travelers

- Re-Wind Machine Operation

- Packaging/Shipping Procedures

- Quality control