Enhanced Aluminum Coatings

Ion Assisted Deposition (IAD) of metallic and dielectric films, performed with four chambers and variable configurations to accommodate large substrates and diverse applications. Reflectors and optics up to 3 meters can be coated. Full mechanical design, fabrication, proof-loading, complete handling plans for accommodating unique hardware and scalable processes to meet larger reflector needs. Surface Optics Corporation’s coatings lab has successfully coated hundreds of flight reflectors.

Chambers

- 3.3 meter (motion controlled e-beam IAD)

- 1.8 meter (motion controlled e-beam IAD)

- 1.2 meter (planetary)

- Small R&D chamber (up to 3 runs per day)

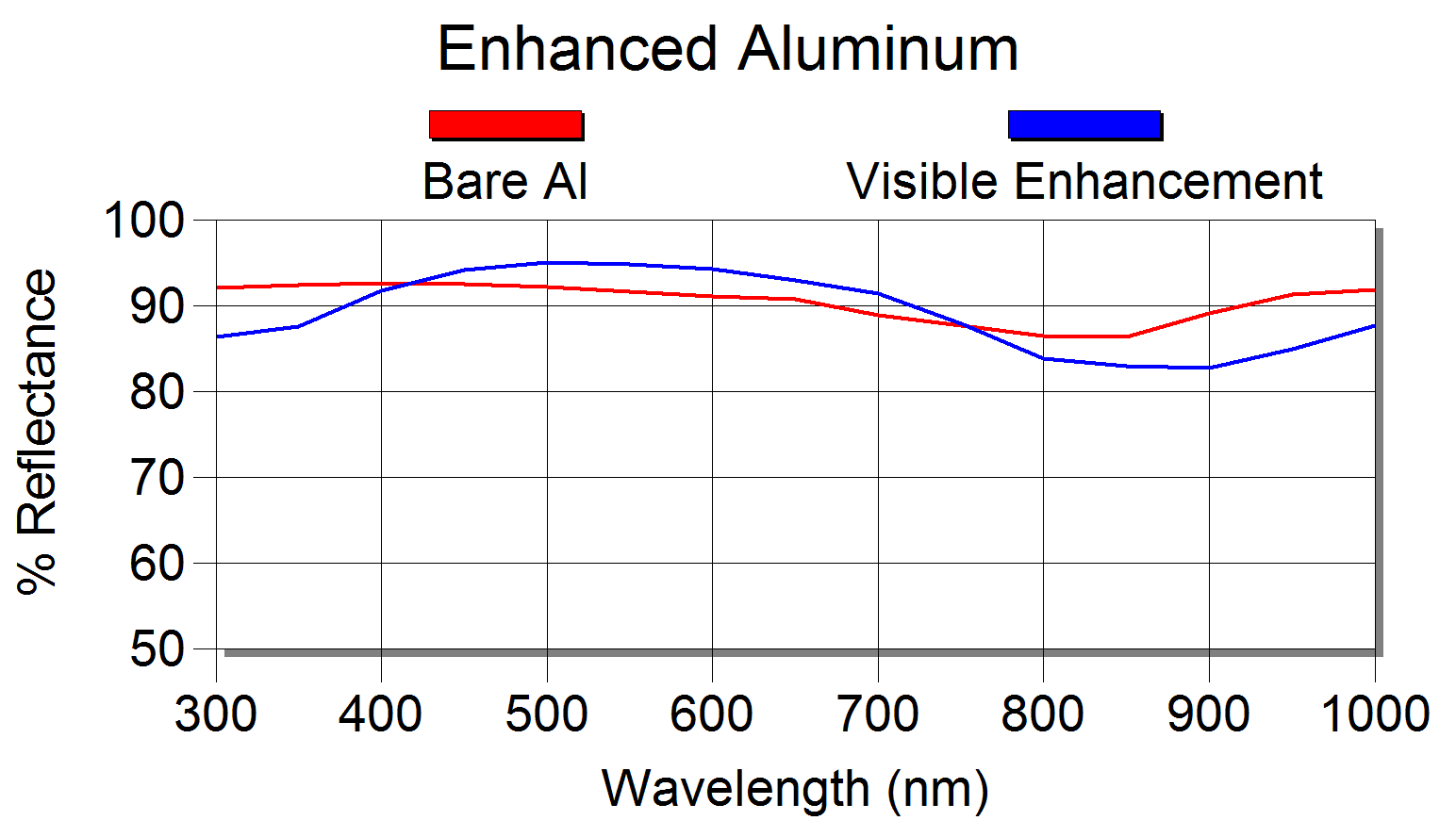

Performance

Bare Al Rmin = ~85.0 400-1000nm

Enhanced Aluminum Rmin 300-1000nm: 82.6%

Enhanced Aluminum Rmax 300-1000nm: 95.0%

Enhanced Aluminum Rave 300-1000nm: 89.3%

Enhanced aluminum Rave 400-700nm : 93.8%

Turnaround time: Flat Substrates up to 5” – 2 weeks

Larger than 5” : Development program built with your statement of work.

Note: theoretical data provided