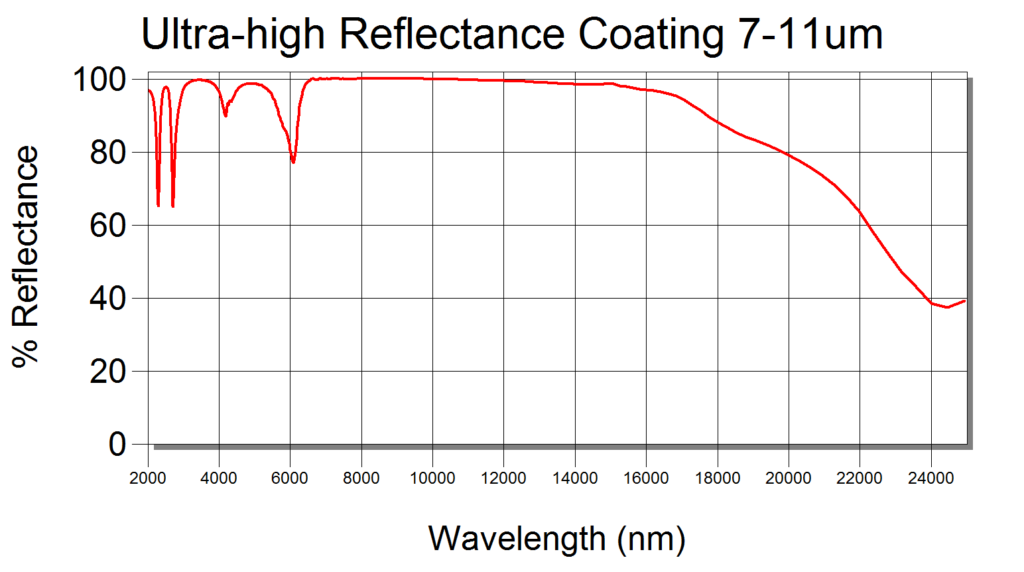

Ultra High Reflectance IR Coatings

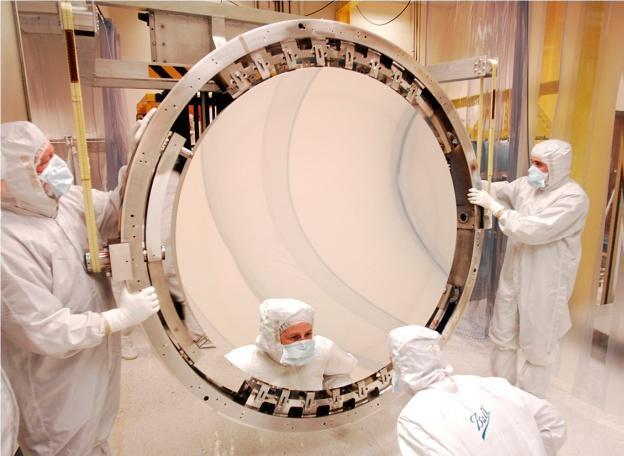

Ion Assisted Deposition (IAD) of metallic and dielectric films, performed with four chambers and variable configurations to accommodate large substrates and diverse applications. Reflectors and optics up to 3 meters can be coated. Full mechanical design, fabrication, proof-loading, complete handling plans for accommodating unique hardware and scalable processes to meet larger reflector needs. Surface Optics Corporation’s coatings lab has successfully coated hundreds of flight reflectors.

See Also Thermal Control Coatings

Chambers

- 3.3 meter (motion controlled e-beam IAD)

- 1.8 meter (motion controlled e-beam IAD)

- 1.2 meter (planetary)

- Small R&D chamber (up to 2 runs per day)

Performance:

Average reflectance 7-11 microns >99.9%.

Emissivity ~ 0.0743