Abstract

Spacecraft experience thermal swings from above +200°C to below –200°C as they move between sunlight and eclipse. Traditional methods, such as fixed-emittance coatings, multilayer insulation, heaters, and mechanical radiators, add mass, consume power, and lack adaptability. Variable Emittance Materials (VEMs) offer an adaptive alternative by dynamically adjusting infrared emissivity to reject heat when hot and conserve heat when cold. This paper reviews key VEM technologies, including passive thermochromic coatings such as vanadium dioxide (VO₂), active electrochromic films, MEMS-based micro-louvers, and emerging metamaterial and shape-morphing radiators. VEMs reduce power requirements, lower mass, and provide autonomous thermal regulation, making them well suited for small satellites and power-limited missions. Surface Optics Corporation is developing VO₂-based and hybrid VEM coatings using roll-to-roll deposition to produce large-area, flexible thermal control films. Continued testing and collaboration are expected to accelerate the transition of VEMs from laboratory development to flight-qualified systems capable of replacing bulky mechanical hardware with lightweight, adaptive surfaces.

Introduction to Variable Emittance Materials (VEMs)

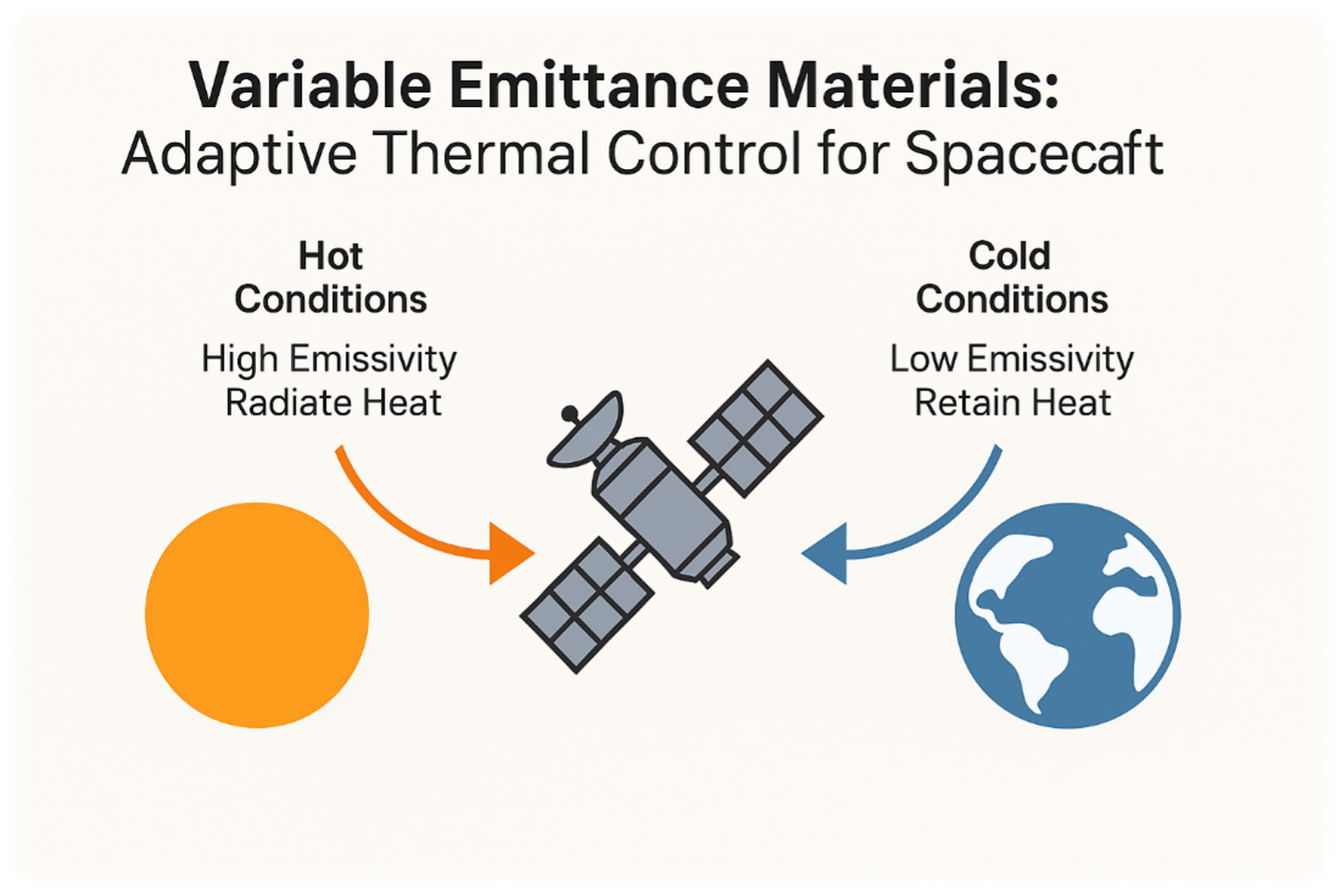

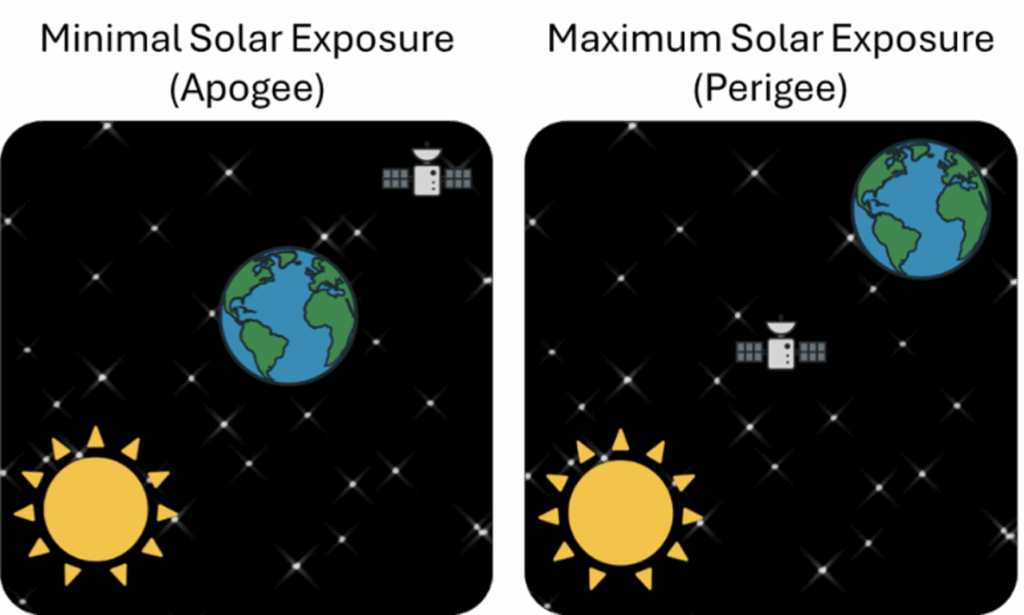

The space environment presents a significant thermal management challenge. As a spacecraft transitions between direct sunlight and eclipse (Figure 1), its external surfaces can experience temperature swings from above +200 °C to below –200 °C within minutes in the most extreme scenario [1]. Traditionally, thermal engineers have addressed these extremes using fixed-emittance radiators, multilayer insulation, and onboard heaters to maintain internal temperatures within mission-critical limits [2], [3].

Figure 1. An illustration of a satellite in orbit around the Earth, demonstrating extreme orbital positions relative to the Sun. (Left) At its apogee position (farthest from the Sun), the satellite is expected to remain relatively cool due to lower solar irradiance. (Right) At its perigee position (closest to the Sun), the satellite experiences its highest thermal load. The actual solar exposure depends on the Earth’s orbital position relative to the Sun and the satellite’s position relative to the Earth. Additionally, the Earth, the Moon, and other celestial bodies radiate heat, further contributing to the satellite’s thermal environment.

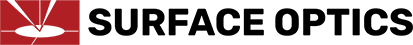

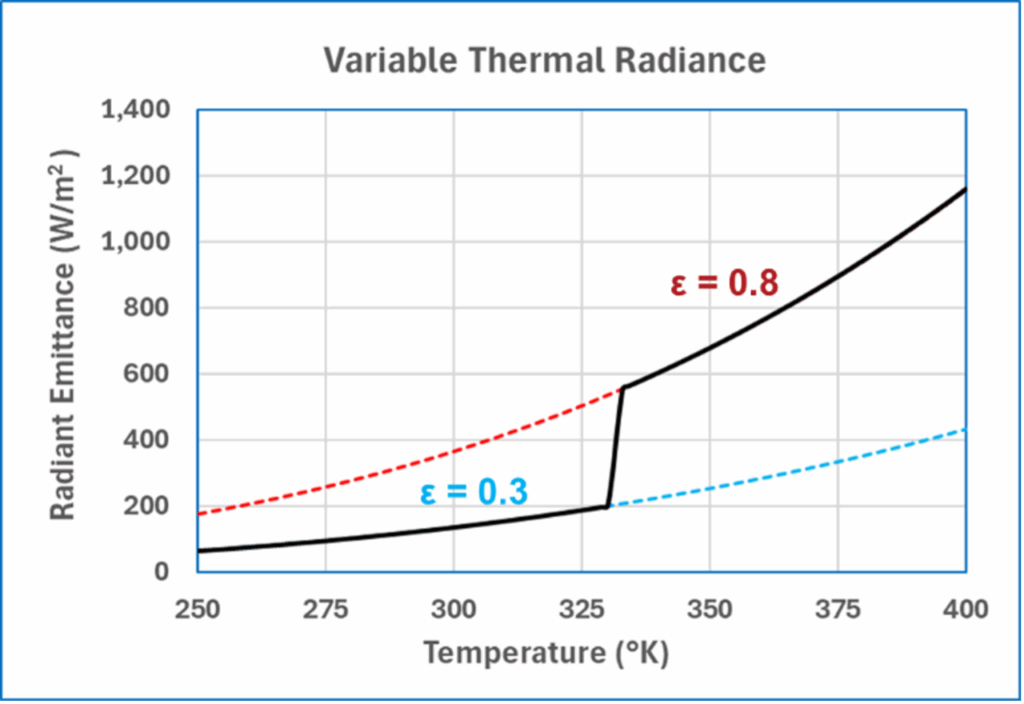

Variable Emittance Materials (VEMs) are an emerging class of thermal control surfaces that respond dynamically to changing conditions. These coatings adjust their infrared emissivity, or how efficiently they radiate heat, either passively with temperature or actively through electrical or optical input. Although these emissivity changes are invisible to the human eye, since they occur in the infrared spectrum, they significantly affect a spacecraft’s thermal behavior. When surface temperatures rise, VEM can increase its emissivity to radiate excess heat. In colder conditions, the same surface can reduce its emissivity to retain thermal energy [4].

This adaptive functionality allows spacecraft surfaces to behave as smart radiators that modulate thermal emission in real time. As a result, VEMs can reduce or eliminate the need for mechanical louvers or resistive heaters and offer a more efficient and compact approach to thermal management. This is especially valuable for missions with tight constraints on volume, power, or mass [5].

Fundamentals of Thermal Control in Space

In space, thermal radiation is the dominant mechanism for heat transfer. The amount of thermal energy a surface emits depends on its temperature and emissivity (ε), a material property that ranges from 0 for a perfect reflector to 1 for an ideal blackbody. Surfaces with high emissivity emit thermal radiation efficiently and cool more rapidly, while low-emissivity surfaces retain heat by limiting infrared radiation loss [6].

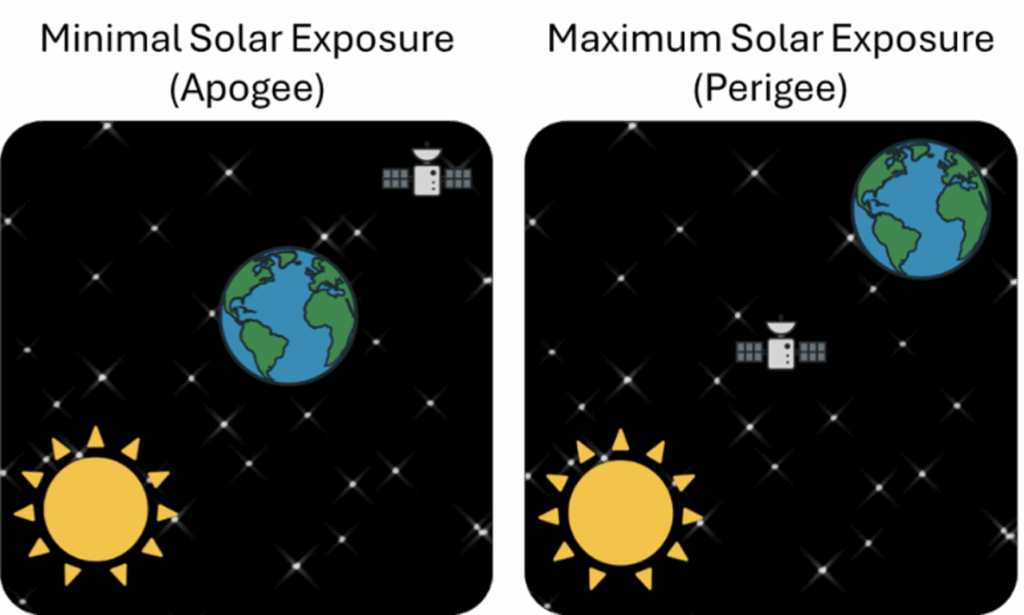

Solar absorptivity (α) is another critical parameter. It describes how much incident solar energy is absorbed by a surface. Effective thermal control coatings are typically engineered with low α to minimize solar heating and high ε to maximize radiative cooling. A spacecraft surface achieves thermal equilibrium by balancing the absorbed solar flux against emitted infrared radiation [7]. Both thermal emissivity and solar absorptance are schematically represented in Figure 2.

Historically, thermal engineers have used materials with static optical properties such as white thermal control paints and optical solar reflectors [8]. These materials offer fixed combinations of α and ε and perform well within a defined thermal regime but cannot adapt across the full range of orbital conditions. This often leads to design trade-offs. A surface optimized for hot, sunlit conditions may perform poorly during eclipse, and vice versa.

VEMs address this limitation by allowing surface emissivity to vary in response to real-time environmental inputs. This dynamic control improves thermal regulation, reduces reliance on bulkier active systems, and provides greater flexibility in spacecraft design. As a result, VEMs offer a promising solution for advanced thermal architectures in future missions.

Traditional Thermal Control Methods (Alternatives to VEMs)

Before the advent of smart materials, aerospace thermal engineers relied on a combination of passive and active techniques to manage extreme temperature variations. These legacy technologies remain in widespread use, and understanding them is important as VEMs are poised to complement or replace certain elements of conventional spacecraft thermal architectures.

- Thermal Coatings and Surface Finishes: Spacecraft are commonly covered in coatings selected for specific absorptivity and emissivity values. For example, multilayer insulation (MLI) blankets and white paints are used to minimize heat loss, while high-emissivity radiator paints enhance heat rejection. These coatings offer fixed optical properties and cannot adapt to changing conditions [9].

- Electrical Heaters: Thermostatically controlled resistive heaters are widely used to prevent components from reaching excessively low temperatures. When a satellite enters a cold environment, such as eclipse or deep space, heaters consume electrical power to compensate for the absence of solar input. While effective, this method draws valuable power and increases mass due to heater elements and wiring [10].

- Variable Conductance Heat Pipes (VCHPs): Heat pipes are passive systems that transfer heat from warm components to radiator surfaces. VCHPs incorporate a working fluid and a gas reservoir that adjusts the condenser length to modulate heat flow. In warm conditions, the gas retracts to maximize thermal conduction; in cold conditions, it expands to reduce the active radiator area and prevent overcooling. This mechanism allows some thermal throttling but does not affect surface emissivity and adds mechanical complexity [11].

- Spacecraft Attitude and Orbit Adjustments: Operators sometimes manage thermal loads by altering the spacecraft’s orientation or orbit. For instance, pointing a different surface toward the Sun or initiating a slow rotational spin can redistribute thermal energy. However, these maneuvers are constrained by mission objectives and are not always viable on a continuous basis [12].

- Mechanical Louvers and Shutters: A longstanding solution for variable radiative control involves thermal louvers, which operate much like miniature Venetian blinds. These assemblies include metal blades that open to expose a high-emissivity radiator or close to insulate it. Early spacecraft and missions such as ESA’s Rosetta probe used passive louvers actuated by bimetallic springs that responded to temperature. In the open state, more heat is radiated; in the closed state, thermal losses are reduced. Although effective and requiring no power input, louvers are often bulky and include moving parts. These characteristics pose challenges for small satellite platforms where mass and volume are highly constrained. Moreover, most louver systems provide an emissivity range of approximately 0.15 to 0.55, which may be insufficient to fully eliminate the need for supplemental heating [13].

- Deployable Radiators: Some spacecraft employ deployable panels that can increase or decrease radiating surface area as needed. These radiators can be extended or rotated outward when heat rejection is required and retracted or rotated edge-on to space to conserve thermal energy. While offering effective control, these systems involve mechanical motion and may introduce operational complexity or failure risk [14].

Each of these methods has demonstrated value in specific mission contexts but often involves trade-offs in mass, volume, complexity, or power consumption. For example, resistive heaters require ongoing power and active control, while mechanical components such as louvers or deployable radiators introduce potential points of failure. Within this landscape, Variable Emittance Materials have emerged as a promising alternative. Rather than relying on moving parts or continuous power input, VEMs regulate heat flow through intrinsic changes in surface properties, offering a lighter, simpler, and more autonomous approach to spacecraft thermal control.

How Variable Emittance Materials Work

A Variable Emittance Material actively changes its infrared emissivity in response to either environmental conditions or an external control signal. The fundamental idea is to emulate natural thermal regulation strategies, such as how some animals modulate blood flow near the skin to control heat loss. A well-designed VEM provides a form of negative thermal feedback: it increases heat dissipation when the spacecraft becomes hot and conserves heat when cold, thereby tending to stabilize temperature automatically. This behavior can be realized through various physical mechanisms, which give rise to several major classes of VEM technologies:

1. Passive Thermochromic Coatings (Temperature-Responsive)

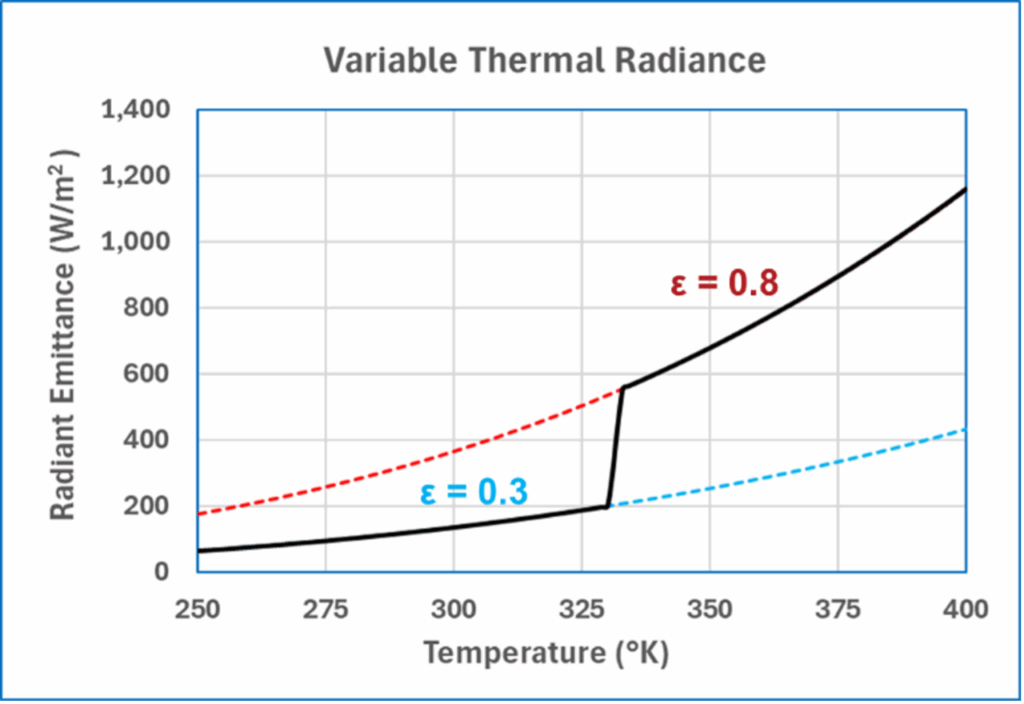

These materials adjust emissivity in response to temperature without requiring any electrical input, making them purely passive. The term “thermochromic” refers to a change in material phase or optical properties at a defined transition temperature. A widely studied example is vanadium dioxide (VO₂), a thermochromic oxide of interest for spacecraft applications. VO₂ exhibits a reversible phase transition around 68 °C (154 °F): below this threshold it exists in a semiconductor phase with low infrared emissivity, while above it transitions to a metallic phase with much higher emissivity (Figure 3). As a result, VO₂-based surfaces automatically increase radiative cooling when hot and reduce it when cool [15]. In one demonstrated design, a VO₂‑coated radiator based on a VO₂/Ge/VO₂/Ag Fabry–Pérot structure achieved emissivity values near 0.78 in its hot (metallic) state and about 0.10 in its cold state, representing a substantial swing in radiative heat rejection capability [16].

Thermochromic coatings are attractive for their simplicity and reliability. They require no electronics, input power, or mechanical parts, making them well suited for long-duration missions. However, several challenges remain. The natural transition temperature of VO₂ may be too high for some spacecraft electronics, prompting research into doped VO₂ variants to lower the switching point. Additionally, VO₂ is susceptible to degradation from atomic oxygen and must be protected to survive the space environment. Nonetheless, thermochromic VEMs represent an elegant approach to phase-change thermal control and offer continuous modulation without the need for power or external commands.

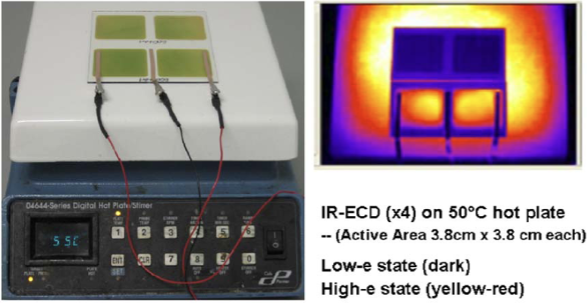

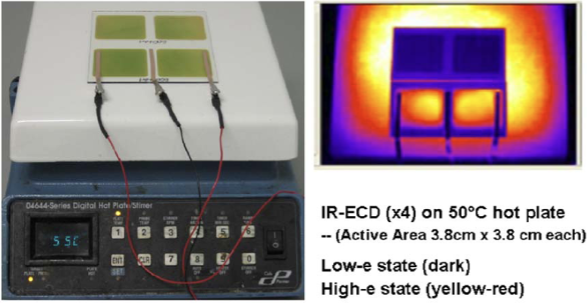

2. Active Electrochromic Surfaces (Voltage-Controllable)

Electrochromic VEMs require a low-voltage electrical input to switch between different emissivity states. These are thin-film devices in which voltage-driven ion exchange or electrochemical reactions alter the optical properties of the surface (Figure 4). A typical electrochromic radiator may consist of a reflective metal substrate, an ion-storage layer, an electrolyte, and a tunable electrochromic layer. When a voltage is applied, ions migrate into the active layer, changing its optical constants and modifying its infrared transparency or absorption [17].

This voltage-controlled architecture allows dynamic adjustment of emissivity to a desired set point. Unlike passive systems, electrochromic devices offer tunability across a continuous range. For instance, a device developed by Eclipse Energy Systems achieved a change in emissivity (Δε) of approximately 0.8 within the 7 to 12 μm thermal infrared band [18]. Contemporary systems use advanced electrochromic materials such as tungsten oxide or conducting polymers, often combined with solid-state ion conductors. These films are flexible, lightweight, and scalable, enabling integration into spacecraft radiator surfaces as thin, conformal coatings.

Electrochromic VEMs typically require only a few volts (1 to 3 V DC) and minimal switching power, often in the microwatt-per-square-centimeter range. Switching times can vary from seconds to minutes, which is acceptable given the slow thermal dynamics of spacecraft. Once set, many electrochromic systems hold their emissivity state without additional power input, either through bistability or infrequent refresh cycles. Several designs have already been tested in low-Earth orbit, including on small satellites and the International Space Station. The key advantages are wide tunability, low mass, and the potential to replace traditional mechanical radiators with film-based alternatives.

3. Micro-Mechanical (MEMS) Radiators

MEMS-based variable radiators combine the principles of mechanical louvers with microfabrication technology. These systems use microscopic actuators to expose or block radiative surfaces, enabling modulation of effective emissivity through physical movement. One prototype involved a carbon-loaded polyimide film (high emissivity) covered by an array of microfabricated flaps that could open or close, thereby switching between radiative and insulated states [19].

Actuation may be driven by thermal bimorphs, electrostatic forces, or magnetic micro-actuators. Some designs function passively through thermal expansion, similar to traditional bimetallic louvers, while others are actively controlled using small voltages. The benefits of MEMS radiators include low mass, batch fabrication compatibility, and fine spatial control of emissivity. They are especially promising for CubeSats and other small spacecraft where traditional mechanical systems are too large or heavy [14].

The main technical hurdle for MEMS devices is ensuring reliability in the space environment, where hundreds or thousands of moving parts must function under vacuum, radiation, and thermal cycling. However, research continues to advance in this area. For example, the European Space Agency has investigated MEMS thermal louvers actuated by solar heating of a micro-scale bimetal coil. These systems could be integrated onto printed circuit boards or small thermal zones, offering localized control and complementing material-based VEMs.

Electrophoretic & Other Novel Approaches

Another intriguing category of active thermal surfaces is electrophoretic emissivity modulation, which operates on principles similar to e-ink displays but affects infrared properties rather than visible light. In an electrophoretic VEM, charged pigment particles—such as infrared-black and infrared-white particles—are suspended in a fluid or gel matrix. When an electric field is applied, these particles migrate. By bringing the darker, high-emissivity particles to the surface, or retracting them to reveal a more reflective background, the system toggles between high and low emissivity states [20].

This technique allows for substantial emissivity contrast and generally requires very little power. Similar to e-ink displays, these devices can hold a selected state without continuous power input. NASA studies from the early 2000s evaluated electrophoretic coatings alongside electrochromic and MEMS-based approaches as candidates for variable emissivity radiator systems [21]. Although not as widely publicized as electrochromics or vanadium dioxide coatings, electrophoretic systems offer distinct advantages. They are lightweight, mechanically simple, and offer analog tunability. The emissivity can be modulated incrementally by adjusting the electric field to control how many pigment particles reach the surface.

However, this approach involves fluid-based systems, which introduce engineering challenges in microgravity environments. Long-term stability of the suspension and potential for particle aggregation must also be addressed. These remain active areas of research and development.

In addition to the primary VEM classes, researchers are exploring new strategies that couple mechanical reconfiguration and material science for dynamic thermal control.

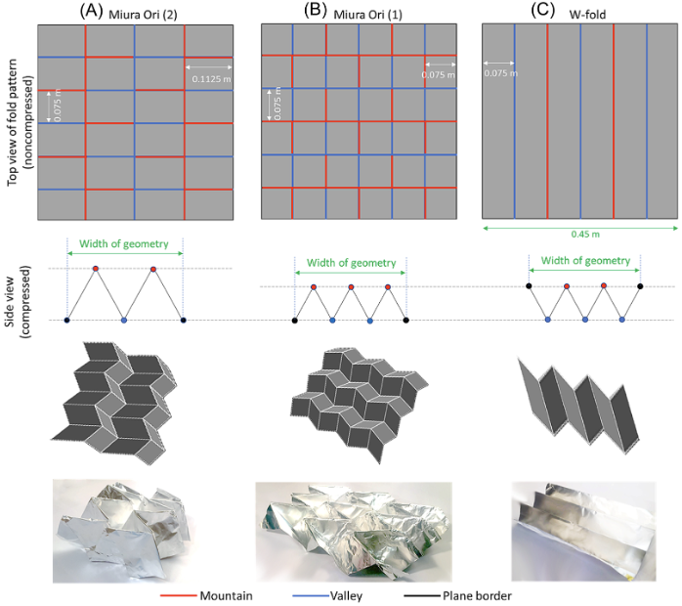

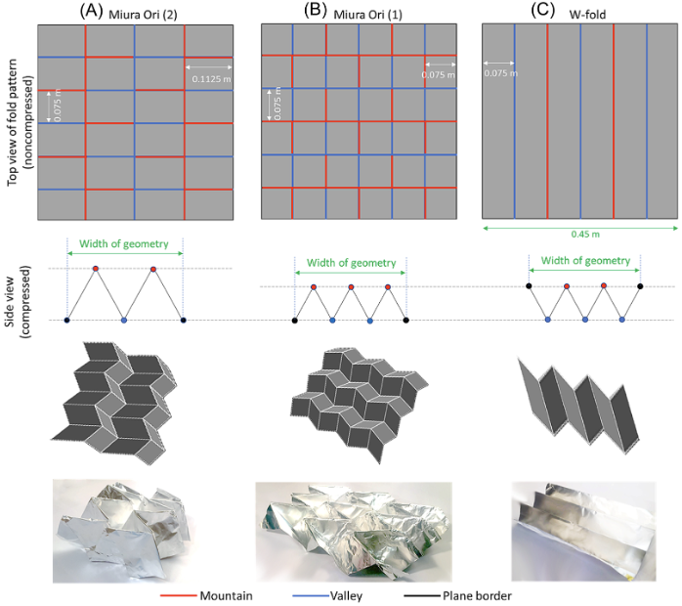

Shape-morphing radiators use materials such as shape memory alloys or electrostatic actuators to alter the physical geometry of a radiator in orbit. One proposed concept, illustrated in Figure 5, involves origami-inspired folding surfaces that can increase or decrease their depth to tune the effective radiative area [22]. By changing the configuration, the radiator modulates how much thermal energy it emits, providing a physical method of emissivity control without relying on coatings alone.

Metamaterials represent another frontier. These are artificially structured surfaces with sub-wavelength features designed to manipulate electromagnetic behavior in ways not found in natural materials. In the context of thermal control, metamaterial surfaces can be engineered to adjust their infrared spectral properties in response to external stimuli, such as temperature changes or applied voltages. This enables precise and potentially rapid modulation of emissivity, tailored to specific wavelength bands [23].

Although still in the research phase, shape-morphing structures and emissive metamaterials may eventually complement or extend existing VEM technologies. Their integration into spacecraft systems could enable highly adaptive and tunable thermal architectures for future missions.

Benefits of VEMs for Aerospace Thermal Engineers

The appeal of Variable Emittance Materials in spacecraft thermal control lies in their simplicity, versatility, and efficiency once implemented. They offer several key advantages that can reshape how thermal engineers approach spacecraft design:

- Passive, Autonomous Thermal Regulation: Thermochromic materials in particular can provide self-regulating thermal control without sensors, controllers, or any power input. The coating itself responds directly to temperature, functioning much like a built-in thermostat. This passive behavior is highly valuable for spacecraft operating in extreme environments with limited or no oversight.

- Reduced Mass and Volume: VEM coatings are typically lightweight thin films that can be applied directly to the spacecraft’s radiator or structural surfaces. Unlike bulky louvers, complex heat pipe assemblies, or large deployable radiators, VEMs require minimal supporting hardware. This reduces system mass, a critical constraint in satellite design, and frees up volume for other payloads or subsystems. For small satellites, the ability to replace heavy thermal hardware with a simple film or coating can be mission-enabling.

- Power Savings: Many active thermal control systems rely on continuous electrical power, whether to operate resistive heaters or to drive mechanical components. In contrast, most VEMs consume little or no power. Electrochromic systems require only a small voltage (typically 1–3 V DC) and minimal current to switch emissivity states. Once switched, the emissivity state is usually maintained with negligible power draw. Passive thermochromic coatings require no power at all. This is especially beneficial for power-limited missions such as CubeSats or deep space probes operating with limited solar input.

- Dynamic Range and Performance: Properly engineered VEMs can offer a wide dynamic range in emissivity. For example, surfaces may switch from an emissivity as low as 0.2 to values exceeding 0.8. This range matches or exceeds the performance of many mechanical louver systems. By maximizing thermal rejection during high heat loads and minimizing radiative losses in cold conditions, VEMs help maintain critical components within a narrow thermal band. This not only improves system efficiency but can also extend the lifespan and reliability of onboard electronics by avoiding thermal cycling extremes.

- Scalability and Flexibility: Because most VEMs are based on film or coating technologies, they can be readily scaled to large areas or applied to irregular surfaces. In principle, an entire spacecraft could be covered with variable-emittance skin. They are also inherently modular. Different zones of the spacecraft can be independently controlled, with one area operating in a high-emissivity state while another remains in a low-emissivity mode. This level of spatial control is difficult to achieve with global heaters or mechanical systems that treat the spacecraft uniformly.

Given these benefits, VEMs are widely regarded as a breakthrough technology for spacecraft thermal control. By reducing system complexity, lowering power requirements, and providing tighter thermal regulation, they have the potential to simplify spacecraft design and significantly reduce development time and cost.

However, technical challenges remain. Space qualification is still ongoing. VEMs must be able to withstand radiation, UV exposure, atomic oxygen, vacuum conditions, and many thermal cycles. Some may degrade or exhibit performance shifts after long-term orbital exposure, making on-orbit validation critical. Recent efforts such as the MISSE-FF flight experiments on the International Space Station are helping build confidence in these technologies [24]. Engineers must also be cautious to avoid secondary effects. For example, electrochromic surfaces must be carefully shielded to avoid electrical interference, and material outgassing must be managed to avoid contamination in vacuum environments.

Outlook and Call for Collaboration

Variable Emittance Materials are redefining spacecraft thermal control, replacing bulky hardware with adaptive coatings that dynamically regulate heat flow. Flight experiments, including the Air Force Research Laboratory’s SPIRRAL mission, highlight their potential, but scalable production and flight qualification remain critical to widespread adoption.

Surface Optics Corporation (SOC) is actively developing next-generation VEM films and has proven control over the thermal properties of vanadium oxide (VO₂) for commercial applications. Building on decades of expertise in precision optical coatings, we are now adapting this capability for space-rated systems.

Our 5‑meter roll-to-roll web coating chamber (shown in Figure 6) enables high-volume fabrication of uniform, high-performance VEM coatings on flexible substrates. These films can be applied to large radiators, deployable panels, and curved spacecraft surfaces, reducing mass and cost while delivering precise, tunable thermal control.

We invite satellite manufacturers, thermal engineers, and aerospace program managers to partner with us to:

- Develop and optimize VO₂‑based and hybrid VEM formulations for mission-specific requirements

- Qualify coatings through joint thermal vacuum and space-environment testing

- Integrate VEM technology into flight demonstrations and operational missions

SOC’s goal is to transition VEMs from lab to orbit, enabling spacecraft that intelligently manage their own thermal environment. Let’s collaborate to make that vision a reality.

References

[1] K. Dong, D. Tseng, J. Li, S. Warkander, J. Yao, and J. Wu, “Reducing temperature swing of space objects with temperature-adaptive solar or radiative coating,” Cell Rep. Phys. Sci., vol. 3, no. 10, p. 101066, Oct. 2022, doi: 10.1016/j.xcrp.2022.101066.

[2] S. Tachikawa, H. Nagano, A. Ohnishi, and Y. Nagasaka, “Advanced Passive Thermal Control Materials and Devices for Spacecraft: A Review,” Int. J. Thermophys., vol. 43, no. 6, Jun. 2022, doi: 10.1007/s10765-022-03010-3.

[3] D. W. Hengeveld, M. M. Mathison, J. E. Braun, E. A. Groll, and A. D. Williams, “Review of Modern Spacecraft Thermal Control Technologies,” HVACR Res., vol. 16, no. 2, pp. 189–220, Mar. 2010, doi: 10.1080/10789669.2010.10390900.

[4] Z. Du et al., “VO2-based intelligent thermal control coating for spacecraft by regulating infrared emittance,” J. Alloys Compd., vol. 895, p. 162679, Feb. 2022, doi: 10.1016/j.jallcom.2021.162679.

[5] S. Taylor, L. Long, R. McBurney, P. Sabbaghi, J. Chao, and L. Wang, “Spectrally-selective vanadium dioxide based tunable metafilm emitter for dynamic radiative cooling,” Sol. Energy Mater. Sol. Cells, vol. 217, p. 110739, Nov. 2020, doi: 10.1016/j.solmat.2020.110739.

[6] J. R. Howell, M. P. Menguc, and R. Siegel, Thermal Radiation Heat Transfer, 0 ed. CRC Press, 2015. doi: 10.1201/b18835.

[7] M. Ozel, “The influence of exterior surface solar absorptivity on thermal characteristics and optimum insulation thickness,” Renew. Energy, vol. 39, no. 1, pp. 347–355, Mar. 2012, doi: 10.1016/j.renene.2011.08.039.

[8] R. C. Youngquist, M. A. Nurge, W. L. Johnson, T. L. Gibson, and J. M. Surma, “Cryogenic Deep Space Thermal Control Coating,” J. Spacecr. Rockets, vol. 55, no. 3, pp. 622–631, May 2018, doi: 10.2514/1.a34019.

[9] N. Kiomarsipour, R. Shoja Razavi, and K. Ghani, “Improvement of spacecraft white thermal control coatings using the new synthesized Zn-MCM-41 pigment,” Dyes Pigments, vol. 96, no. 2, pp. 403–406, Feb. 2013, doi: 10.1016/j.dyepig.2012.08.019.

[10] C. Y. Han and J.-M. Choi, “Thermal analysis of spacecraft propulsion system and its validation,” KSME Int. J., vol. 18, no. 5, pp. 847–856, May 2004, doi: 10.1007/bf02990304.

[11] G. Birur, J. Rodriquez, and M. Nikitkin, “Loop Heat Pipe Applications for Thermal Control of Martian Landers/Rovers,” Jet Propulsion Laboratory, El Segundo, CA, 20010003945, Feb. 1999. [Online]. Available: https://ntrs.nasa.gov/citations/20010003945

[12] A. L. Barth, A. Walker, P. Putman, and O. Ma, “Determining an Optimal Attitude Profile for Thermal Management of a Remote Sensing Cubesat,” in ASCEND 2021, Las Vegas, Nevada & Virtual: American Institute of Aeronautics and Astronautics, Nov. 2021. doi: 10.2514/6.2021-4101.

[13] D. T. Cowan, “Actively Controlled Louver for Human Spacecraft Radiator Ultraviolet (UV), Dust, and Freeze Protection”.

[14] H. Nagano, Y. Nagasaka, and A. Ohnishi, “Simple Deployable Radiator with Autonomous Thermal Control Function,” J. Thermophys. Heat Transf., vol. 20, no. 4, pp. 856–864, Oct. 2006, doi: 10.2514/1.17988.

[15] K. Sun et al., “VO2 Thermochromic Metamaterial-Based Smart Optical Solar Reflector,” ACS Photonics, vol. 5, no. 6, pp. 2280–2286, Jun. 2018, doi: 10.1021/acsphotonics.8b00119.

[16] Q. Xu et al., “VO2-Based Spacecraft Smart Radiator with High Emissivity Tunability and Protective Layer,” Nanomaterials, vol. 14, no. 16, p. 1348, Aug. 2024, doi: 10.3390/nano14161348.

[17] F. Lang, H. Wang, S. Zhang, J. Liu, and H. Yan, “Review on Variable Emissivity Materials and Devices Based on Smart Chromism,” Int. J. Thermophys., vol. 39, no. 1, Jan. 2018, doi: 10.1007/s10765-017-2329-0.

[18] H. Demiryont and D. Moorehead, “Electrochromic emissivity modulator for spacecraft thermal management,” Sol. Energy Mater. Sol. Cells, vol. 93, no. 12, pp. 2075–2078, Dec. 2009, doi: 10.1016/j.solmat.2009.02.025.

[19] S. Z. Cao, X. K. Chen, G. Wu, J. P. Yang, and R. Wang, “Micro Louvers for Micro and Nano-Satellites Thermal Control,” Adv. Mater. Res., vol. 317–319, pp. 1658–1661, Aug. 2011, doi: 10.4028/www.scientific.net/amr.317-319.1658.

[20] J. Chrun, A. Da Silva, C. Vancaeyzeele, F. Vidal, P.-H. Aubert, and L. Dupont, “Electrophoretic displays for IR emissivity modulation and temperature control,” J. Mater. Chem. C, vol. 11, no. 1, pp. 141–150, 2023, doi: 10.1039/d2tc04147b.

[21] G. Subramaniam, “3-D Photonic Band Gap Crystals,” The Univerity of Alabama, Huntsville, AL.

[22] F. Ahmed, M. Khatamifar, W. Lin, and R. Situ, “Thermal performance of dynamic, origami‐inspired geometries: An experimental study,” Heat Transf., vol. 52, no. 5, pp. 3799–3816, Jul. 2023, doi: 10.1002/htj.22852.

[23] Q. Chu, F. Zhong, X. Shang, Y. Zhang, S. Zhu, and H. Liu, “Controlling thermal emission with metasurfaces and its applications,” Nanophotonics, vol. 13, no. 8, pp. 1279–1301, Apr. 2024, doi: 10.1515/nanoph-2023-0754.

[24] J. Perkins, “Revolutionizing space-based thermal systems,” Air Force Research Laboratory Public Affairs. [Online]. Available: https://www.afrl.af.mil/News/Article-Display/Article/3977263/revolutionizing-space-based-thermal-systems-afrls-spirral-launch-on-spx-31

Abstract

Spacecraft experience thermal swings from above +200 °C to below –200 °C as they move between sunlight and eclipse, and traditional methods such as fixed-emittance coatings, multilayer insulation, heaters, and mechanical radiators add mass, consume power, and lack adaptability. Variable Emittance Materials (VEMs) offer an adaptive alternative by dynamically adjusting infrared emissivity to reject heat when hot and conserve heat when cold. This paper reviews key VEM technologies, including passive thermochromic coatings such as vanadium dioxide (VO₂), active electrochromic films, MEMS-based micro-louvers, and emerging metamaterial and shape-morphing radiators. VEMs reduce power requirements, lower mass, and provide autonomous thermal regulation, making them well suited for small satellites and power-limited missions. Surface Optics Corporation is developing VO₂-based and hybrid VEM coatings using roll-to-roll deposition to produce large-area, flexible thermal control films. Continued testing and collaboration are expected to accelerate the transition of VEMs from laboratory development to flight-qualified systems capable of replacing bulky mechanical hardware with lightweight, adaptive surfaces.

Introduction to Variable Emittance Materials (VEMs)

The space environment presents a significant thermal management challenge. As a spacecraft transitions between direct sunlight and eclipse (Figure 1), its external surfaces can experience temperature swings from above +200 °C to below –200 °C within minutes in the most extreme scenario [1]. Traditionally, thermal engineers have addressed these extremes using fixed-emittance radiators, multilayer insulation, and onboard heaters to maintain internal temperatures within mission-critical limits [2], [3].

Figure 1. An illustration of a satellite in orbit around the Earth, demonstrating extreme orbital positions relative to the Sun. (Left) At its apogee position (farthest from the Sun), the satellite is expected to remain relatively cool due to lower solar irradiance. (Right) At its perigee position (closest to the Sun), the satellite experiences its highest thermal load. The actual solar exposure depends on the Earth’s orbital position relative to the Sun and the satellite’s position relative to the Earth. Additionally, the Earth, the Moon, and other celestial bodies radiate heat, further contributing to the satellite’s thermal environment.

Variable Emittance Materials (VEMs) are an emerging class of thermal control surfaces that respond dynamically to changing conditions. These coatings adjust their infrared emissivity, or how efficiently they radiate heat, either passively with temperature or actively through electrical or optical input. Although these emissivity changes are invisible to the human eye, since they occur in the infrared spectrum, they significantly affect a spacecraft’s thermal behavior. When surface temperatures rise, VEM can increase its emissivity to radiate excess heat. In colder conditions, the same surface can reduce its emissivity to retain thermal energy [4].

This adaptive functionality allows spacecraft surfaces to behave as smart radiators that modulate thermal emission in real time. As a result, VEMs can reduce or eliminate the need for mechanical louvers or resistive heaters and offer a more efficient and compact approach to thermal management. This is especially valuable for missions with tight constraints on volume, power, or mass [5].

Fundamentals of Thermal Control in Space

In space, thermal radiation is the dominant mechanism for heat transfer. The amount of thermal energy a surface emits depends on its temperature and emissivity (ε), a material property that ranges from 0 for a perfect reflector to 1 for an ideal blackbody. Surfaces with high emissivity emit thermal radiation efficiently and cool more rapidly, while low-emissivity surfaces retain heat by limiting infrared radiation loss [6].

Solar absorptivity (α) is another critical parameter. It describes how much incident solar energy is absorbed by a surface. Effective thermal control coatings are typically engineered with low α to minimize solar heating and high ε to maximize radiative cooling. A spacecraft surface achieves thermal equilibrium by balancing the absorbed solar flux against emitted infrared radiation [7]. Both thermal emissivity and solar absorptance are schematically represented in Figure 2.

Historically, thermal engineers have used materials with static optical properties such as white thermal control paints and optical solar reflectors [8]. These materials offer fixed combinations of α and ε and perform well within a defined thermal regime but cannot adapt across the full range of orbital conditions. This often leads to design trade-offs. A surface optimized for hot, sunlit conditions may perform poorly during eclipse, and vice versa.

VEMs address this limitation by allowing surface emissivity to vary in response to real-time environmental inputs. This dynamic control improves thermal regulation, reduces reliance on bulkier active systems, and provides greater flexibility in spacecraft design. As a result, VEMs offer a promising solution for advanced thermal architectures in future missions.

Traditional Thermal Control Methods (Alternatives to VEMs)

Before the advent of smart materials, aerospace thermal engineers relied on a combination of passive and active techniques to manage extreme temperature variations. These legacy technologies remain in widespread use, and understanding them is important as VEMs are poised to complement or replace certain elements of conventional spacecraft thermal architectures.

Thermal Coatings and Surface Finishes: Spacecraft are commonly covered in coatings selected for specific absorptivity and emissivity values. For example, multilayer insulation (MLI) blankets and white paints are used to minimize heat loss, while high-emissivity radiator paints enhance heat rejection. These coatings offer fixed optical properties and cannot adapt to changing conditions [9].

Electrical Heaters: Thermostatically controlled resistive heaters are widely used to prevent components from reaching excessively low temperatures. When a satellite enters a cold environment, such as eclipse or deep space, heaters consume electrical power to compensate for the absence of solar input. While effective, this method draws valuable power and increases mass due to heater elements and wiring [10].

Variable Conductance Heat Pipes (VCHPs): Heat pipes are passive systems that transfer heat from warm components to radiator surfaces. VCHPs incorporate a working fluid and a gas reservoir that adjusts the condenser length to modulate heat flow. In warm conditions, the gas retracts to maximize thermal conduction; in cold conditions, it expands to reduce the active radiator area and prevent overcooling. This mechanism allows some thermal throttling but does not affect surface emissivity and adds mechanical complexity [11].

Spacecraft Attitude and Orbit Adjustments: Operators sometimes manage thermal loads by altering the spacecraft’s orientation or orbit. For instance, pointing a different surface toward the Sun or initiating a slow rotational spin can redistribute thermal energy. However, these maneuvers are constrained by mission objectives and are not always viable on a continuous basis [12].

Mechanical Louvers and Shutters: A longstanding solution for variable radiative control involves thermal louvers, which operate much like miniature Venetian blinds. These assemblies include metal blades that open to expose a high-emissivity radiator or close to insulate it. Early spacecraft and missions such as ESA’s Rosetta probe used passive louvers actuated by bimetallic springs that responded to temperature. In the open state, more heat is radiated; in the closed state, thermal losses are reduced. Although effective and requiring no power input, louvers are often bulky and include moving parts. These characteristics pose challenges for small satellite platforms where mass and volume are highly constrained. Moreover, most louver systems provide an emissivity range of approximately 0.15 to 0.55, which may be insufficient to fully eliminate the need for supplemental heating [13].

Deployable Radiators: Some spacecraft employ deployable panels that can increase or decrease radiating surface area as needed. These radiators can be extended or rotated outward when heat rejection is required and retracted or rotated edge-on to space to conserve thermal energy. While offering effective control, these systems involve mechanical motion and may introduce operational complexity or failure risk [14].

Each of these methods has demonstrated value in specific mission contexts but often involves trade-offs in mass, volume, complexity, or power consumption. For example, resistive heaters require ongoing power and active control, while mechanical components such as louvers or deployable radiators introduce potential points of failure. Within this landscape, Variable Emittance Materials have emerged as a promising alternative. Rather than relying on moving parts or continuous power input, VEMs regulate heat flow through intrinsic changes in surface properties, offering a lighter, simpler, and more autonomous approach to spacecraft thermal control.

How Variable Emittance Materials Work

A Variable Emittance Material actively changes its infrared emissivity in response to either environmental conditions or an external control signal. The fundamental idea is to emulate natural thermal regulation strategies, such as how some animals modulate blood flow near the skin to control heat loss. A well-designed VEM provides a form of negative thermal feedback: it increases heat dissipation when the spacecraft becomes hot and conserves heat when cold, thereby tending to stabilize temperature automatically. This behavior can be realized through various physical mechanisms, which give rise to several major classes of VEM technologies:

1. Passive Thermochromic Coatings (Temperature-Responsive)

These materials adjust emissivity in response to temperature without requiring any electrical input, making them purely passive. The term “thermochromic” refers to a change in material phase or optical properties at a defined transition temperature. A widely studied example is vanadium dioxide (VO₂), a thermochromic oxide of interest for spacecraft applications. VO₂ exhibits a reversible phase transition around 68 °C (154 °F): below this threshold it exists in a semiconductor phase with low infrared emissivity, while above it transitions to a metallic phase with much higher emissivity (Figure 3). As a result, VO₂-based surfaces automatically increase radiative cooling when hot and reduce it when cool [15]. In one demonstrated design, a VO₂‑coated radiator based on a VO₂/Ge/VO₂/Ag Fabry–Pérot structure achieved emissivity values near 0.78 in its hot (metallic) state and about 0.10 in its cold state, representing a substantial swing in radiative heat rejection capability [16].

Thermochromic coatings are attractive for their simplicity and reliability. They require no electronics, input power, or mechanical parts, making them well suited for long-duration missions. However, several challenges remain. The natural transition temperature of VO₂ may be too high for some spacecraft electronics, prompting research into doped VO₂ variants to lower the switching point. Additionally, VO₂ is susceptible to degradation from atomic oxygen and must be protected to survive the space environment. Nonetheless, thermochromic VEMs represent an elegant approach to phase-change thermal control and offer continuous modulation without the need for power or external commands.

2. Active Electrochromic Surfaces (Voltage-Controllable)

Electrochromic VEMs require a low-voltage electrical input to switch between different emissivity states. These are thin-film devices in which voltage-driven ion exchange or electrochemical reactions alter the optical properties of the surface (Figure 4). A typical electrochromic radiator may consist of a reflective metal substrate, an ion-storage layer, an electrolyte, and a tunable electrochromic layer. When a voltage is applied, ions migrate into the active layer, changing its optical constants and modifying its infrared transparency or absorption [17].

This voltage-controlled architecture allows dynamic adjustment of emissivity to a desired set point. Unlike passive systems, electrochromic devices offer tunability across a continuous range. For instance, a device developed by Eclipse Energy Systems achieved a change in emissivity (Δε) of approximately 0.8 within the 7 to 12 μm thermal infrared band [18]. Contemporary systems use advanced electrochromic materials such as tungsten oxide or conducting polymers, often combined with solid-state ion conductors. These films are flexible, lightweight, and scalable, enabling integration into spacecraft radiator surfaces as thin, conformal coatings.

Electrochromic VEMs typically require only a few volts (1 to 3 V DC) and minimal switching power, often in the microwatt-per-square-centimeter range. Switching times can vary from seconds to minutes, which is acceptable given the slow thermal dynamics of spacecraft. Once set, many electrochromic systems hold their emissivity state without additional power input, either through bistability or infrequent refresh cycles. Several designs have already been tested in low-Earth orbit, including on small satellites and the International Space Station. The key advantages are wide tunability, low mass, and the potential to replace traditional mechanical radiators with film-based alternatives.

3. Micro-Mechanical (MEMS) Radiators

MEMS-based variable radiators combine the principles of mechanical louvers with microfabrication technology. These systems use microscopic actuators to expose or block radiative surfaces, enabling modulation of effective emissivity through physical movement. One prototype involved a carbon-loaded polyimide film (high emissivity) covered by an array of microfabricated flaps that could open or close, thereby switching between radiative and insulated states [19].

Actuation may be driven by thermal bimorphs, electrostatic forces, or magnetic micro-actuators. Some designs function passively through thermal expansion, similar to traditional bimetallic louvers, while others are actively controlled using small voltages. The benefits of MEMS radiators include low mass, batch fabrication compatibility, and fine spatial control of emissivity. They are especially promising for CubeSats and other small spacecraft where traditional mechanical systems are too large or heavy [14].

The main technical hurdle for MEMS devices is ensuring reliability in the space environment, where hundreds or thousands of moving parts must function under vacuum, radiation, and thermal cycling. However, research continues to advance in this area. For example, the European Space Agency has investigated MEMS thermal louvers actuated by solar heating of a micro-scale bimetal coil. These systems could be integrated onto printed circuit boards or small thermal zones, offering localized control and complementing material-based VEMs.

Electrophoretic & Other Novel Approaches

Another intriguing category of active thermal surfaces is electrophoretic emissivity modulation, which operates on principles similar to e-ink displays but affects infrared properties rather than visible light. In an electrophoretic VEM, charged pigment particles—such as infrared-black and infrared-white particles—are suspended in a fluid or gel matrix. When an electric field is applied, these particles migrate. By bringing the darker, high-emissivity particles to the surface, or retracting them to reveal a more reflective background, the system toggles between high and low emissivity states [20].

This technique allows for substantial emissivity contrast and generally requires very little power. Similar to e-ink displays, these devices can hold a selected state without continuous power input. NASA studies from the early 2000s evaluated electrophoretic coatings alongside electrochromic and MEMS-based approaches as candidates for variable emissivity radiator systems [21]. Although not as widely publicized as electrochromics or vanadium dioxide coatings, electrophoretic systems offer distinct advantages. They are lightweight, mechanically simple, and offer analog tunability. The emissivity can be modulated incrementally by adjusting the electric field to control how many pigment particles reach the surface.

However, this approach involves fluid-based systems, which introduce engineering challenges in microgravity environments. Long-term stability of the suspension and potential for particle aggregation must also be addressed. These remain active areas of research and development.

In addition to the primary VEM classes, researchers are exploring new strategies that couple mechanical reconfiguration and material science for dynamic thermal control.

Shape-morphing radiators use materials such as shape memory alloys or electrostatic actuators to alter the physical geometry of a radiator in orbit. One proposed concept, illustrated in Figure 5, involves origami-inspired folding surfaces that can increase or decrease their depth to tune the effective radiative area [22]. By changing the configuration, the radiator modulates how much thermal energy it emits, providing a physical method of emissivity control without relying on coatings alone.

Metamaterials represent another frontier. These are artificially structured surfaces with sub-wavelength features designed to manipulate electromagnetic behavior in ways not found in natural materials. In the context of thermal control, metamaterial surfaces can be engineered to adjust their infrared spectral properties in response to external stimuli, such as temperature changes or applied voltages. This enables precise and potentially rapid modulation of emissivity, tailored to specific wavelength bands [23].

Although still in the research phase, shape-morphing structures and emissive metamaterials may eventually complement or extend existing VEM technologies. Their integration into spacecraft systems could enable highly adaptive and tunable thermal architectures for future missions.

Benefits of VEMs for Aerospace Thermal Engineers

The appeal of Variable Emittance Materials in spacecraft thermal control lies in their simplicity, versatility, and efficiency once implemented. They offer several key advantages that can reshape how thermal engineers approach spacecraft design:

Passive, Autonomous Thermal Regulation: Thermochromic materials in particular can provide self-regulating thermal control without sensors, controllers, or any power input. The coating itself responds directly to temperature, functioning much like a built-in thermostat. This passive behavior is highly valuable for spacecraft operating in extreme environments with limited or no oversight.

Reduced Mass and Volume: VEM coatings are typically lightweight thin films that can be applied directly to the spacecraft’s radiator or structural surfaces. Unlike bulky louvers, complex heat pipe assemblies, or large deployable radiators, VEMs require minimal supporting hardware. This reduces system mass, a critical constraint in satellite design, and frees up volume for other payloads or subsystems. For small satellites, the ability to replace heavy thermal hardware with a simple film or coating can be mission-enabling.

Power Savings: Many active thermal control systems rely on continuous electrical power, whether to operate resistive heaters or to drive mechanical components. In contrast, most VEMs consume little or no power. Electrochromic systems require only a small voltage (typically 1–3 V DC) and minimal current to switch emissivity states. Once switched, the emissivity state is usually maintained with negligible power draw. Passive thermochromic coatings require no power at all. This is especially beneficial for power-limited missions such as CubeSats or deep space probes operating with limited solar input.

Dynamic Range and Performance: Properly engineered VEMs can offer a wide dynamic range in emissivity. For example, surfaces may switch from an emissivity as low as 0.2 to values exceeding 0.8. This range matches or exceeds the performance of many mechanical louver systems. By maximizing thermal rejection during high heat loads and minimizing radiative losses in cold conditions, VEMs help maintain critical components within a narrow thermal band. This not only improves system efficiency but can also extend the lifespan and reliability of onboard electronics by avoiding thermal cycling extremes.

Scalability and Flexibility: Because most VEMs are based on film or coating technologies, they can be readily scaled to large areas or applied to irregular surfaces. In principle, an entire spacecraft could be covered with variable-emittance skin. They are also inherently modular. Different zones of the spacecraft can be independently controlled, with one area operating in a high-emissivity state while another remains in a low-emissivity mode. This level of spatial control is difficult to achieve with global heaters or mechanical systems that treat the spacecraft uniformly.

Given these benefits, VEMs are widely regarded as a breakthrough technology for spacecraft thermal control. By reducing system complexity, lowering power requirements, and providing tighter thermal regulation, they have the potential to simplify spacecraft design and significantly reduce development time and cost.

However, technical challenges remain. Space qualification is still ongoing. VEMs must be able to withstand radiation, UV exposure, atomic oxygen, vacuum conditions, and many thermal cycles. Some may degrade or exhibit performance shifts after long-term orbital exposure, making on-orbit validation critical. Recent efforts such as the MISSE-FF flight experiments on the International Space Station are helping build confidence in these technologies [24]. Engineers must also be cautious to avoid secondary effects. For example, electrochromic surfaces must be carefully shielded to avoid electrical interference, and material outgassing must be managed to avoid contamination in vacuum environments.

Outlook and Call for Collaboration

Variable Emittance Materials are redefining spacecraft thermal control, replacing bulky hardware with adaptive coatings that dynamically regulate heat flow. Flight experiments, including the Air Force Research Laboratory’s SPIRRAL mission, highlight their potential, but scalable production and flight qualification remain critical to widespread adoption.

Surface Optics Corporation (SOC) is actively developing next-generation VEM films and has proven control over the thermal properties of vanadium oxide (VO₂) for commercial applications. Building on decades of expertise in precision optical coatings, we are now adapting this capability for space-rated systems.

Our 5‑meter roll-to-roll web coating chamber (shown in Figure 6) enables high-volume fabrication of uniform, high-performance VEM coatings on flexible substrates. These films can be applied to large radiators, deployable panels, and curved spacecraft surfaces, reducing mass and cost while delivering precise, tunable thermal control.

We invite satellite manufacturers, thermal engineers, and aerospace program managers to partner with us to:

(1) Develop and optimize VO₂‑based and hybrid VEM formulations for mission-specific requirements

(2) Qualify coatings through joint thermal vacuum and space-environment testing

(3) Integrate VEM technology into flight demonstrations and operational missions

SOC’s goal is to transition VEMs from lab to orbit, enabling spacecraft that intelligently manage their own thermal environment. Let’s collaborate to make that vision a reality.

References

[1] K. Dong, D. Tseng, J. Li, S. Warkander, J. Yao, and J. Wu, “Reducing temperature swing of space objects with temperature-adaptive solar or radiative coating,” Cell Rep. Phys. Sci., vol. 3, no. 10, p. 101066, Oct. 2022, doi: 10.1016/j.xcrp.2022.101066.

[2] S. Tachikawa, H. Nagano, A. Ohnishi, and Y. Nagasaka, “Advanced Passive Thermal Control Materials and Devices for Spacecraft: A Review,” Int. J. Thermophys., vol. 43, no. 6, Jun. 2022, doi: 10.1007/s10765-022-03010-3.

[3] D. W. Hengeveld, M. M. Mathison, J. E. Braun, E. A. Groll, and A. D. Williams, “Review of Modern Spacecraft Thermal Control Technologies,” HVACR Res., vol. 16, no. 2, pp. 189–220, Mar. 2010, doi: 10.1080/10789669.2010.10390900.

[4] Z. Du et al., “VO2-based intelligent thermal control coating for spacecraft by regulating infrared emittance,” J. Alloys Compd., vol. 895, p. 162679, Feb. 2022, doi: 10.1016/j.jallcom.2021.162679.

[5] S. Taylor, L. Long, R. McBurney, P. Sabbaghi, J. Chao, and L. Wang, “Spectrally-selective vanadium dioxide based tunable metafilm emitter for dynamic radiative cooling,” Sol. Energy Mater. Sol. Cells, vol. 217, p. 110739, Nov. 2020, doi: 10.1016/j.solmat.2020.110739.

[6] J. R. Howell, M. P. Menguc, and R. Siegel, Thermal Radiation Heat Transfer, 0 ed. CRC Press, 2015. doi: 10.1201/b18835.

[7] M. Ozel, “The influence of exterior surface solar absorptivity on thermal characteristics and optimum insulation thickness,” Renew. Energy, vol. 39, no. 1, pp. 347–355, Mar. 2012, doi: 10.1016/j.renene.2011.08.039.

[8] R. C. Youngquist, M. A. Nurge, W. L. Johnson, T. L. Gibson, and J. M. Surma, “Cryogenic Deep Space Thermal Control Coating,” J. Spacecr. Rockets, vol. 55, no. 3, pp. 622–631, May 2018, doi: 10.2514/1.a34019.

[9] N. Kiomarsipour, R. Shoja Razavi, and K. Ghani, “Improvement of spacecraft white thermal control coatings using the new synthesized Zn-MCM-41 pigment,” Dyes Pigments, vol. 96, no. 2, pp. 403–406, Feb. 2013, doi: 10.1016/j.dyepig.2012.08.019.

[10] C. Y. Han and J.-M. Choi, “Thermal analysis of spacecraft propulsion system and its validation,” KSME Int. J., vol. 18, no. 5, pp. 847–856, May 2004, doi: 10.1007/bf02990304.

[11] G. Birur, J. Rodriquez, and M. Nikitkin, “Loop Heat Pipe Applications for Thermal Control of Martian Landers/Rovers,” Jet Propulsion Laboratory, El Segundo, CA, 20010003945, Feb. 1999. [Online]. Available: https://ntrs.nasa.gov/citations/20010003945

[12] A. L. Barth, A. Walker, P. Putman, and O. Ma, “Determining an Optimal Attitude Profile for Thermal Management of a Remote Sensing Cubesat,” in ASCEND 2021, Las Vegas, Nevada & Virtual: American Institute of Aeronautics and Astronautics, Nov. 2021. doi: 10.2514/6.2021-4101.

[13] D. T. Cowan, “Actively Controlled Louver for Human Spacecraft Radiator Ultraviolet (UV), Dust, and Freeze Protection”.

[14] H. Nagano, Y. Nagasaka, and A. Ohnishi, “Simple Deployable Radiator with Autonomous Thermal Control Function,” J. Thermophys. Heat Transf., vol. 20, no. 4, pp. 856–864, Oct. 2006, doi: 10.2514/1.17988.

[15] K. Sun et al., “VO2 Thermochromic Metamaterial-Based Smart Optical Solar Reflector,” ACS Photonics, vol. 5, no. 6, pp. 2280–2286, Jun. 2018, doi: 10.1021/acsphotonics.8b00119.

[16] Q. Xu et al., “VO2-Based Spacecraft Smart Radiator with High Emissivity Tunability and Protective Layer,” Nanomaterials, vol. 14, no. 16, p. 1348, Aug. 2024, doi: 10.3390/nano14161348.

[17] F. Lang, H. Wang, S. Zhang, J. Liu, and H. Yan, “Review on Variable Emissivity Materials and Devices Based on Smart Chromism,” Int. J. Thermophys., vol. 39, no. 1, Jan. 2018, doi: 10.1007/s10765-017-2329-0.

[18] H. Demiryont and D. Moorehead, “Electrochromic emissivity modulator for spacecraft thermal management,” Sol. Energy Mater. Sol. Cells, vol. 93, no. 12, pp. 2075–2078, Dec. 2009, doi: 10.1016/j.solmat.2009.02.025.

[19] S. Z. Cao, X. K. Chen, G. Wu, J. P. Yang, and R. Wang, “Micro Louvers for Micro and Nano-Satellites Thermal Control,” Adv. Mater. Res., vol. 317–319, pp. 1658–1661, Aug. 2011, doi: 10.4028/www.scientific.net/amr.317-319.1658.

[20] J. Chrun, A. Da Silva, C. Vancaeyzeele, F. Vidal, P.-H. Aubert, and L. Dupont, “Electrophoretic displays for IR emissivity modulation and temperature control,” J. Mater. Chem. C, vol. 11, no. 1, pp. 141–150, 2023, doi: 10.1039/d2tc04147b.

[21] G. Subramaniam, “3-D Photonic Band Gap Crystals,” The Univerity of Alabama, Huntsville, AL.

[22] F. Ahmed, M. Khatamifar, W. Lin, and R. Situ, “Thermal performance of dynamic, origami‐inspired geometries: An experimental study,” Heat Transf., vol. 52, no. 5, pp. 3799–3816, Jul. 2023, doi: 10.1002/htj.22852.

[23] Q. Chu, F. Zhong, X. Shang, Y. Zhang, S. Zhu, and H. Liu, “Controlling thermal emission with metasurfaces and its applications,” Nanophotonics, vol. 13, no. 8, pp. 1279–1301, Apr. 2024, doi: 10.1515/nanoph-2023-0754.

[24] J. Perkins, “Revolutionizing space-based thermal systems,” Air Force Research Laboratory Public Affairs. [Online]. Available: https://www.afrl.af.mil/News/Article-Display/Article/3977263/revolutionizing-space-based-thermal-systems-afrls-spirral-launch-on-spx-31