Surface Optics Corporation (SOC) has been selected for the Missile Defense Agency’s Scalable Homeland Innovative Enterprise Layered Defense (SHIELD) contract—a historic 10-year, $151 billion initiative to support the development of the next-generation missile defense shield directed by President Trump’s January 27, 2025, Executive Order, “The Iron Dome for America.”

The executive order directs the Department of Defense to develop and deploy a comprehensive defense system to protect the United States against ballistic, hypersonic, and advanced cruise missiles, as well as other next-generation aerial attacks. The SHIELD contract enables MDA and other Department of Defense organizations to rapidly acquire technologies supporting the layered missile defense architecture mandated by the executive order.

“We look forward to bringing nearly 50 years of optical sensing expertise to support America’s homeland defense alongside the nation’s leading defense contractors,” said Marian Geremia, Chief Executive Officer at SOC. “Our core capabilities address multiple SHIELD requirements, including multispectral imaging for threat detection and tracking, material characterization for signature analysis, and space-qualified coatings for defense assets. We’re ready to compete for task orders that advance this critical mission.”

Hypersonic Threat Detection and Tracking

Surface Optics is already delivering solutions that address hypersonic missile threats through the Hypersonic Spectral Imaging Detection Sensor (HySIDS) program, which tackles one of missile defense’s most difficult challenges: early detection and tracking of hypersonic threats invisible to radar due to plasma shielding.

“Using SOC’s LightShift™ spectral-imaging platform, HySIDS detects the unique spectral radiance of hypersonic plumes and aero-heated vehicle surfaces from tactically significant ranges,” said Mark Dombrowski, President and Chief Technical Officer at SOC. “Operating at full video rates with 32 simultaneous spectral bands, the system maintains the spatial coherence and temporal continuity essential for tracking targets moving more than a mile per second.”

HySIDS builds on Surface Optics’ decades of experience developing operational EO/IR instruments for defense applications, combining spectral imaging system development, advanced sensor design, and real-time algorithm implementation. The program demonstrates SOC’s ability to translate research concepts into operational prototypes through a tightly integrated process of modeling, design, fabrication, and field validation—bridging fundamental R&D to deployable capability in support of the SHIELD mission.

Optical Properties Measurements for Signature Modeling

Founded in 1976, Surface Optics quickly became a trusted lab for optical properties measurements in the U.S. aerospace community. Its work has long supported missile defense, including contributions to some of the core tools used in threat analysis. The company provided key measurements for the Optical Signature Code (OSC), a national standard used to predict the infrared signatures of threats and decoys across their flight paths. Surface Optics’ founder, R.S. Dummer, also wrote the core analytic code at the center of the OSC.

Today, Surface Optics manufactures advanced reflectometer instrumentation and continues to provide expert optical property characterization services, including directional hemispherical reflectance and BRDF/BTDF measurements, supplying the quantitative reflectance data that signature models require to predict how missiles, decoys, and backgrounds appear to missile-defense sensors across viewing angles and wavelengths.

These measurement capabilities are fundamental to understanding threat signatures and validating sensor performance—directly supporting SHIELD’s requirements for advanced tracking and discrimination. SOC instrumentation enables customers to bring these characterization capabilities in-house, accelerating development of novel materials and surface structures for intercept vehicles and other SHIELD requirements.

Thin-Film Vacuum Deposition Coatings for Space

The Surface Optics Coatings Lab develops precision, vacuum-deposited thin-film coatings for satellites and spaceflight hardware, where optical and thermal performance determine mission success. SOC has supported NASA/JPL science missions and major aerospace contractors, including Lockheed Martin, L3Harris, and Northrop Grumman, safely processing hundreds of satellite reflectors through the SOC Coatings Lab.

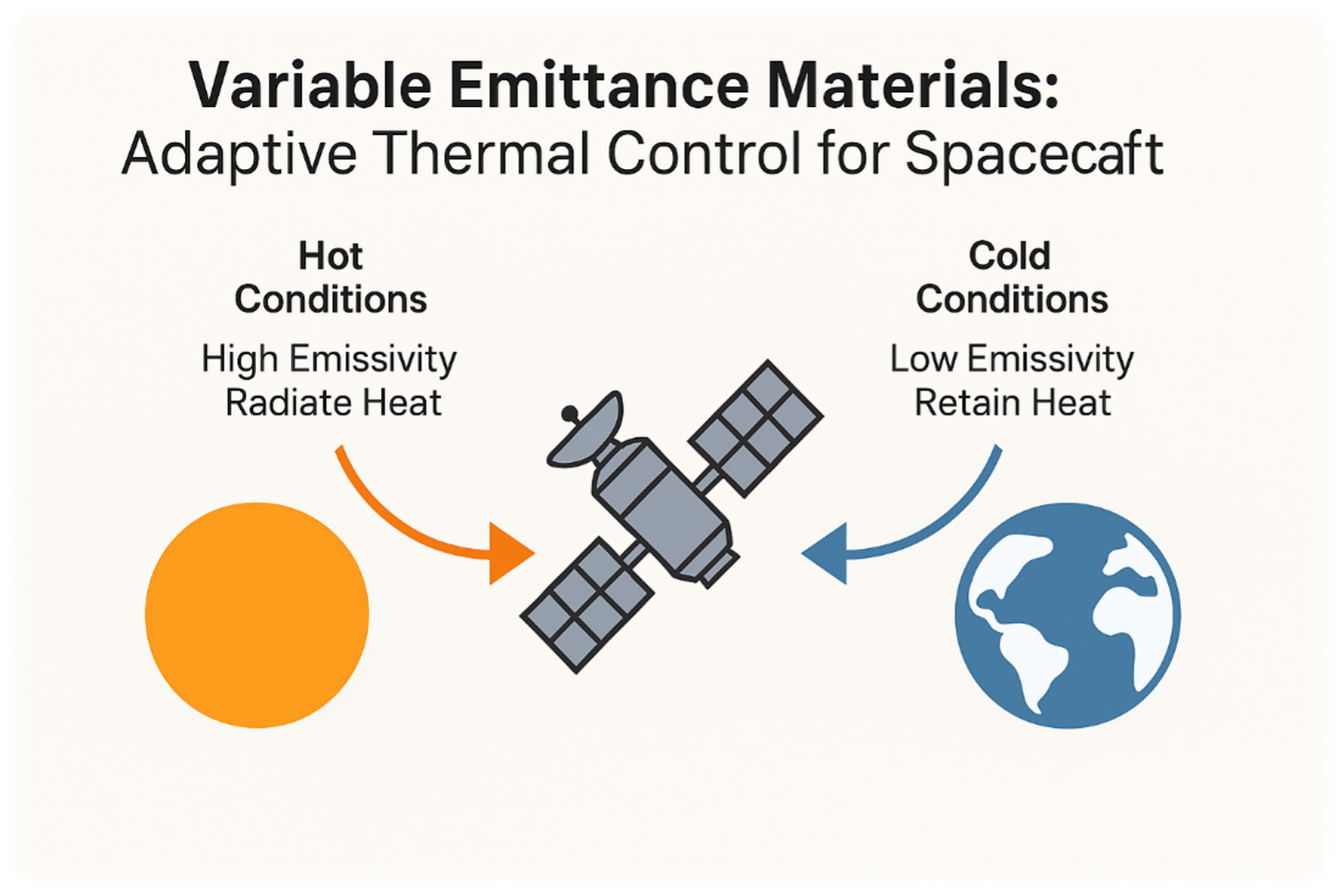

SOC is prepared to support the development of space-based defense assets, which require thermal control coatings to maintain sensors, electronics, and structures within safe temperature limits during the extreme hot-cold cycles of the space environment. These coatings are essential for extending mission lifetimes and ensuring operational reliability. The lab actively develops new coating processes to meet evolving spacecraft thermal requirements, with current work focused on variable-emittance material (VEM) films that enable adaptive thermal control. SOC has demonstrated control over the thermal properties of vanadium oxide (VO₂) for commercial applications and is adapting this capability for space-rated systems.

SOC’s 5-meter roll-to-roll web coating chamber enables high-volume fabrication of uniform, high-performance coatings on flexible substrates. These films can be applied to large radiators, deployable panels, and curved spacecraft surfaces, reducing mass and cost while maintaining precise thermal control. The lab’s low-observable coating capabilities help satellites and high-altitude assets reduce their signatures, increasing survivability in contested environments.

GET IN TOUCH