Reliable data on solar reflectance and thermal emittance are crucial for developing cool roofing and paving materials to combat Urban Heat Island effects and comply with green building regulations. Explore how Surface Optics handheld 410 Series Reflectometers compare to bench-top instrumentation for these measurements.

An urban heat island (UHI) refers to the phenomenon where urban areas experience significantly higher temperatures compared to their surrounding rural areas. Human activities and modifications to the landscape within urban environments primarily cause this temperature difference.

Factors contributing to the urban heat island effect include the absorption and retention of heat by materials like asphalt and concrete in urban infrastructure, the reduction of vegetation, which limits shade and evaporative cooling, heat generated by transportation and industrial processes, and altered wind patterns due to urban structures, hindering natural ventilation and resulting in the trapping of heat within cities.

Building codes often incorporate provisions related to heat island reduction to promote the construction and retrofitting of buildings and infrastructure that minimizes their contribution to the UHI effect. Heat island reduction strategies include using cool roofing materials and reflective paving for roads, sidewalks, courtyards, and parking structures. To meet these green building provisions and improve cool roofing and hardscape materials, roofing manufacturers and environmental engineering researchers require reliable performance data on solar reflectance and thermal emittance.

Solar reflectance and emittance values quantify a material’s ability to reflect sunlight and emit absorbed heat, respectively. These values are essential in assessing the performance of materials for cool roofing and paving applications.

Solar Reflectance

Solar reflectance, often denoted by the symbol “R,” represents the fraction of incoming solar radiation that is reflected by a material’s surface. It is expressed as a decimal or percentage, with higher values indicating greater reflectivity. A material with high solar reflectance absorbs less solar energy, resulting in lower surface temperatures and reduced heat transfer into the building or surrounding environment. Cool roof materials typically have high solar reflectance to minimize heat absorption and mitigate the urban heat island effect.

Thermal Emittance

Thermal emittance, denoted by the symbol “ε” or “E,” measures a material’s ability to emit absorbed heat as thermal radiation. It represents the proportion of thermal energy (infrared radiation) emitted by a material’s surface relative to that emitted by a perfect blackbody at the same temperature. Thermal emittance values range from 0 to 1, with higher values indicating greater emissivity. Materials with high thermal emittance efficiently release absorbed heat, allowing them to cool down faster and maintain lower surface temperatures. This property is crucial for cool roofing and paving materials to enhance their overall cooling performance.

Solar Reflectance Measurement Technique

The best standard technique for determining solar reflectance uses spectrophotometric measurements, with an integrating sphere to determine the reflectance at each different wavelength. The solar reflectance is then determined by an averaging process using a standard solar spectrum. This method is documented by ASTM (American Society for Testing and Materials) in standards E903 and E892.

When this data is not available, other, less detailed measurements are utilized. Manufacturers sometimes measure the visible reflectance. This is the reflectance in the visual part of the solar spectrum, with wavelengths of 400 to 700 nanometers. Usually, the visible reflectance is correlated with the solar reflectance, but the two quantities are not equal. For example, a good white coating with a solar reflectance of 0.8 typically has a visible reflectance of about 0.9.

Large laboratory reflectometers have been used to measure solar reflectance but more recently, researchers and manufacturers have adopted handheld portable reflectometers as they provide comparable solar reflectance and emittance data, with the advantage of being easily carried onto buildings and around manufacturing facilities.

Reflectometer Performance Evaluation

The Surface Optics measurements lab performed an in-house data comparison of the 410-Solar portable reflectometer vs. the Agilent Cary 5000 UV-Vis-NIR Spectrophotometer to evaluate the accuracy and performance for determining the solar reflectance of sample roofing materials.

410-Solar handheld configuration with ET100 measurement head. The 410-Solar (orange) measures solar reflectance and the ET100 (red) measures thermal emittance.

The 410-Solar Reflectometer covers the 330-2500 nm solar spectrum, measuring total, diffuse, and specular reflectance over seven discrete bands. It uses a modified integrating sphere with tungsten filament light source, and is NIST traceable through custom calibration references. The 410-Solar is portable and modular, allowing for easy interchangeability between field use and the lab configuration.

Cary 5000 lab reflectometer is a top-of-the-line laboratory reflectometer developed by Agilent. For this test, it was configured with a spectral resolution of 5nm covering the 330-2500nm solar spectrum. It also uses an integrating sphere and was calibrated with NIST traceable Spectralon.

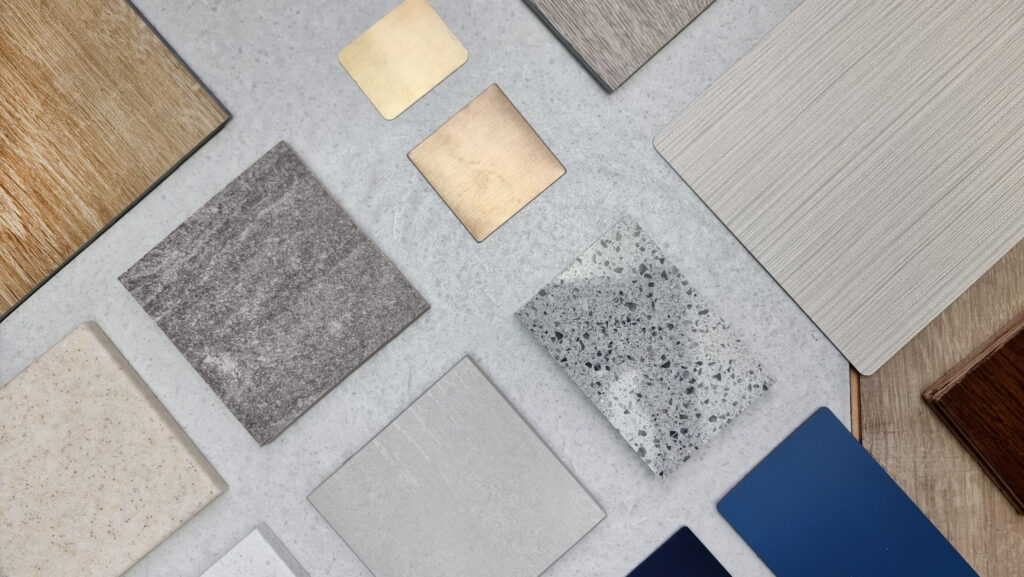

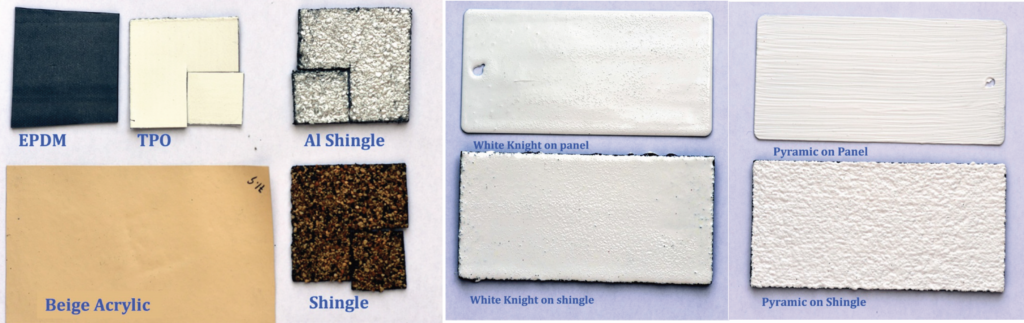

Samples

Images of some of the building samples that were measured for solar reflectance data by the 410-Solar and the Cary 5000.

Results

The results of this in-house data comparison of total reflectance data for all samples as measured by the 410-Solar and the Cary 5000 can be seen below. The reflectance measurements produced by the Cary 5000 and the 410-Solar were highly consistent. Each sample was measured three times and reflectance values were averaged.

| Coating Sample | CARY 5000 | 410-Solar |

|---|---|---|

| White Knight Plus on Panel | 0.82 +/- .02 | 0.82 +/- .02 |

| White Knight Plus on Shingle | 0.80 +/- .02 | 0.80 +/- .02 |

| Pyramic on Panel | 0.82 +/- .02 | 0.80 +/- .02 |

| Pyramic on Shingle | 0.82 +/- .02 | 0.81 +/- .02 |

| White Coating | 0.84 +/- .02 | 0.84 +/- .02 |

| TPO | 0.77 +/- .02 | 0.76 +/- .02 |

| Beige Acrylic | 0.69 +/- .02 | 0.70 +/- .02 |

| Aluminized Shingle | 0.64 +/- .02 | 0.64 +/- .02 |

| EPDM | 0.16 +/- .015 | 0.15 +/- .02 |

| Shingle | 0.17 +/- .015 | 0.17 +/- .02 |

Graph of Cary 5000 vs 410-Solar for Sample Material

The red line shows Cary 5000 spectral data compared with rectangles representing 410-Solar in-band data for the pyramic on panel coating sample.

In Conclusion

In conclusion, the data produced by the two instruments was highly comparable. The difference in accuracy between the two instruments was no greater than 2% total reflectance. The handheld 410-Solar’s performance in this study held up very well against the more complex and pricier laboratory benchtop instrument. Here are several advantages of the 410-Solar compared to other portable reflectometers.

- Modular design allowing for easy interchangeability between a handheld “pistol grip”.

- configuration for use in the field and a tabletop configuration for use in the lab.

- Modified integrating sphere for increased accuracy.

- Measures total, specular, and diffuse reflectance over 7 discrete bands for a total of 21 data points for each measurement.

- Ruggedized touch screen dislay with user friend software interface and step-by-step calibration and measurement process. Data immediately visible on the display and can also be exported to spreadsheet.

- Data and software stored on SD card for high data security.