Over 30 years of experience in the design, development, and application of precision thermal control and reflectance coatings on critical spaceflight hardware.

Surface Optics has full capability to address unique hardware from conception to completion. Our ability to create specialized fixturing includes mechanical design, fabrication, proof loading, and complete handling plans. Surface Optics has safely processed hundreds of flight reflectors and other aerospace hardware through our coating facility.

Key Coating Technology

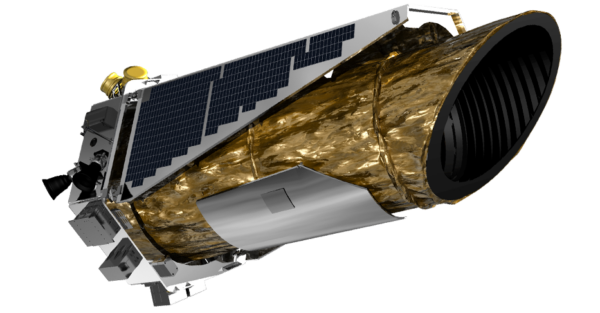

Your Trusted Partner Across Decades of Space Missions

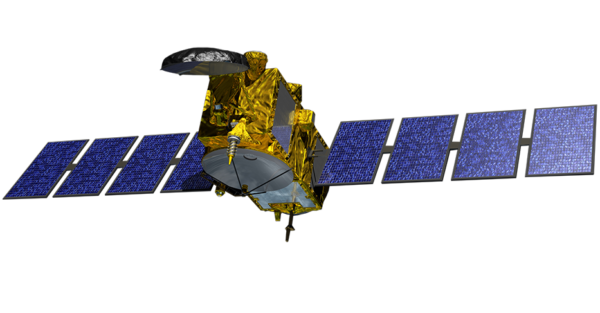

Launched 1999

Launched 2001

Launched 2009

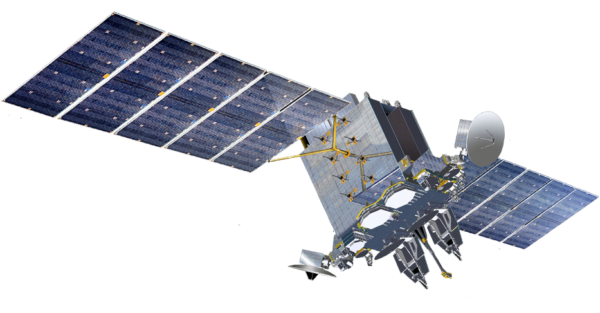

Launched 2010

Launched 2012

Launched 2016

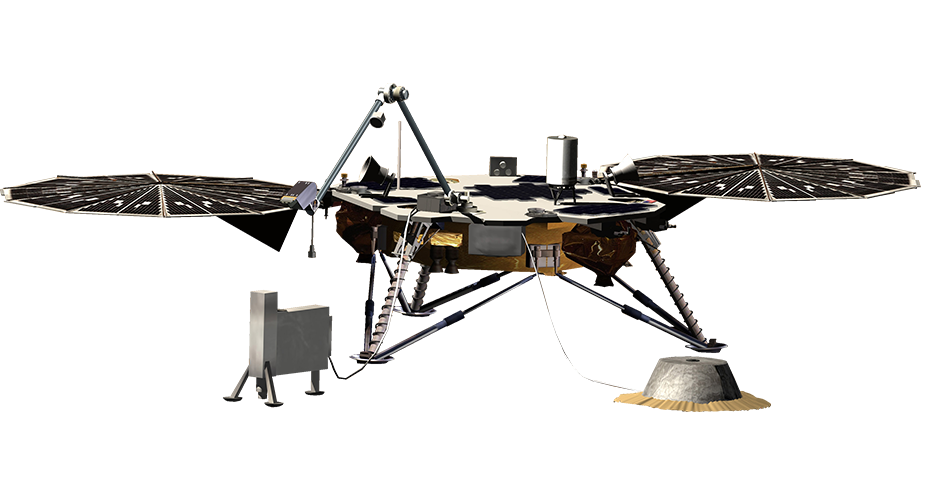

Launched 2018

Launched 2020

Launched 2022

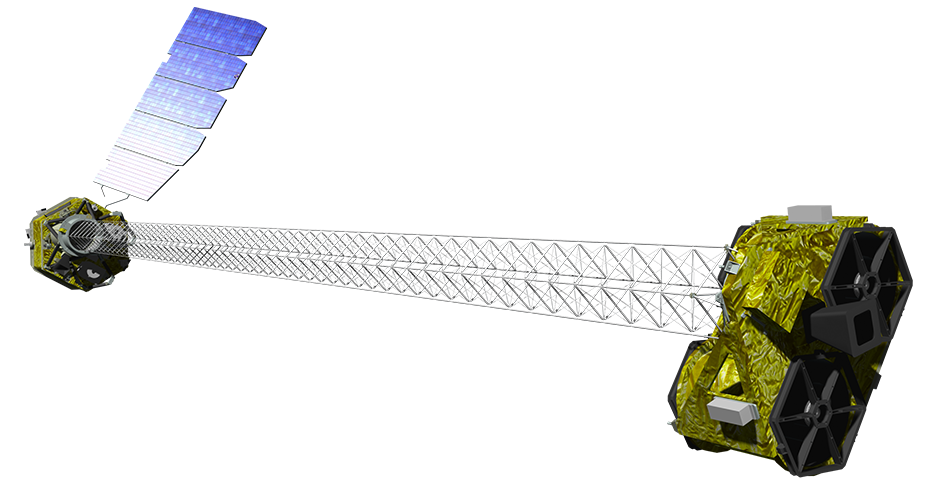

Estimated Launch: 2025

Thermal Control Coating Process

HIGH REFLECTANCE COATING FOR KEPLER PRIMARY MIRROR

In order to produce a space telescope system with sufficient sensitivity to detect relatively small planets, a very high reflectance coating on the primary mirror was required. Using ion assisted evaporation, Surface Optics Corp. applied a protective nine-layer silver coating to enhance reflection and a dielectric interference coating to minimize the formation of color centers and atmospheric moisture absorption.