Surface Optics is a focused provider of vacuum deposition coatings for the aerospace and defense industries. We have over 30 years of space hardware coating experience.

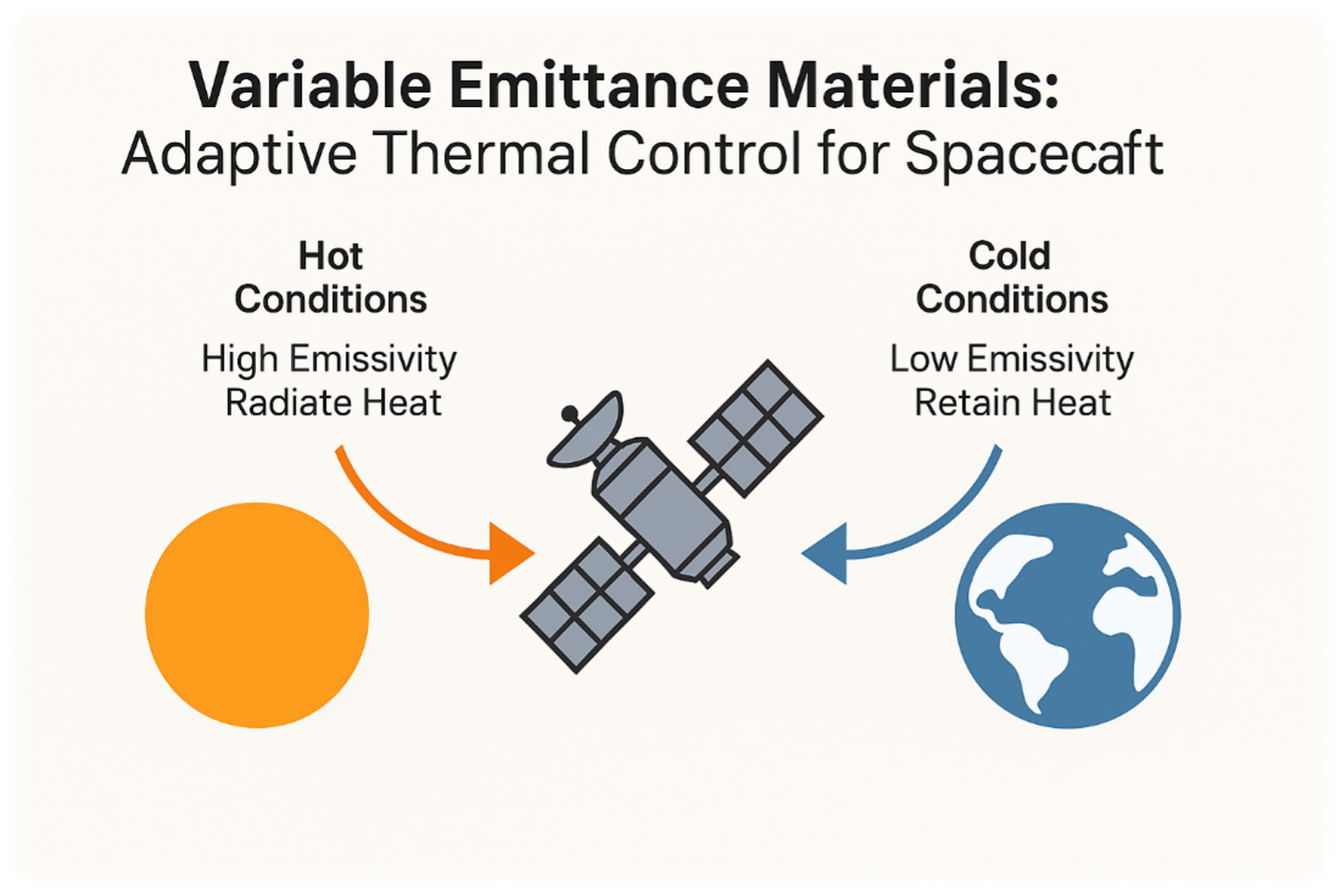

Our coatings lab offers large chambers and clean rooms, a custom job environment, one-of-a-kind coating hardware, significant space program heritage, and on-site world-class metrology. We manufacture vacuum deposited coatings using several techniques standard in the coating industry: resistively heated thermal evaporation, electron beam evaporation, and ion beam assisted deposition.

Utilize our standard coating services or work with us to develop a custom solution that meets your needs. We perform batch-to-batch adjustment and verification with our in-house measurement lab. Our ability to scale, test, and measure within the same facility allows us to rapidly bring your development project from prototype to production. Capability to scale for high volume production and large substrates.

Applications

Our thin-film vacuum coating processes are used to produce:

Facilities

Our ISO9001 and AS9100 registered coating facility is designed to handle projects of all sizes efficiently and cost-effectively. Whether you’re working on small-scale R&D prototypes or large-scale production runs, we offer flexible solutions with our versatile coating chambers.

Coating Technology |

Applications |

Technology Status |

|---|---|---|

Multi-source E-beam Evaporation |

Reflective & Transmissive coatings: optical, IR, RF |

Industry standard |

Crystal Rate Monitoring for High Volume Production |

Allow crystals to be changed automatically. Dual head with up to 48 crystals per e-beam source |

Proprietary |

Ion Assisted Deposition |

Layer stacking of higher density material (crystalline), index control, durability |

Industry standard |

Jori Source Deposition for Dielectric Layers |

Mechanical protection, stress and emissivity management, low temp-hi rate deposition |

Industry standard |

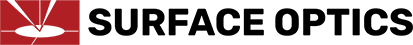

Low Observable Coatings |

Tailored thermal control properties |

Qualified delivery to programs of record |

Low Temperature Coating of Polymer Substrates |

Polyimide web, Plastic lens, Nano-laminate Structures |

Proprietary |

Moving Source Coating Platform |

Enables coating of parts as large as chamber |

Proprietary |