Since its launch in 2018, the Qatar Environment and Energy Research Institute (QEERI) ‘s Solar Consortium has emerged as a leading force in solar technology research. Situated at Hamad Bin Khalifa University (HBKU), the consortium focuses on real-world challenges solar energy systems face in harsh desert environments.

Dr. Veronica Bermudez, Senior Research Director of QEERI’s Energy Center, said, “Our aim with the Solar Consortium is to bring together researchers, technology producers, project developers, and local authorities from the solar energy field, to shape a common focus on practical tests of solar-based devices and systems within Qatar’s desert environment.”

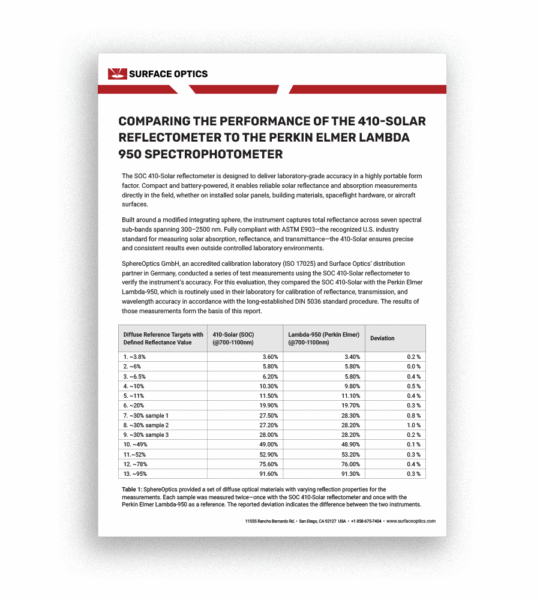

A major research initiative at QEERI is investigating how factors like cleaning methods, environmental exposure, and material properties impact the durability and performance of photovoltaic (PV) modules’ antireflective coatings (ARCs). Desert regions tend to have high soiling rates and little rain, resulting in the need to clean photovoltaic (PV) systems regularly. Large PV plants can have more than a million modules, making manual cleaning impractical and driving the adoption of robot PV cleaning machines in arid regions. Tens of thousands of cleaning robots have already been deployed in just a handful of soiling-prone countries. 1

A key question is whether such machines abrade the antireflective coatings on PV modules, potentially degrading their performance and lifespan. Additional concerns include the optimal schedule for performing cleaning. QEERI’s abrasion project addresses this issue through extensive field testing, laboratory simulations, and its state-of-the-art 35,000 m Outdoor Test Facility (OTF) and PV Reliability Lab.

a rotating linear brush, installed at the QEERI

Outdoor Test Facility. Image Credit: QEERI

“The great thing about the Solar Consortium’s abrasion project is that it provides real-world results. The modules, cleaning machine and testing environment are exactly those found in commercial PV plants in arid regions. The data will provide a valuable link between laboratory test standards and what really happens to module coatings in the field,” said Dr. Ben Figgis, Research Program Manager at QEERI’s OTF (PV Tech, 2021).

Since around 90% of PV modules are now manufactured with an anti-reflective coating (ARC) to improve light transmission (and, therefore, module power) by around 2%–3%, protecting the durability of these coatings is critical for maintaining peak module performance. The ARC typically consists of a thin film of silica nano-particles in a porous structure, which helps achieve the desired refractive index but makes the coating more susceptible to mechanical damage.

One of the critical tools in QEERI’s abrasion research is the Surface Optics handheld integrating-sphere 410-Solar reflectometer. QEERI scientists reported “that it produced valid and repeatable measurements for both crystalline silicon and thin-film modules (“valid” because the measured reflectivities of new modules were in the expected range of 1.5–3%, and “repeatable” because similar values were obtained when multiple measurements were made of the same individual module as well as different modules of the same type). These demonstrations indicate that portable reflectometers are useful to characterize the ARC of PV modules in the field.” 2

reflectance at QEERI facility. Image Credit:

QEERI.

This real-world data is crucial, as laboratory-based abrasion tests often fall short in replicating the exact conditions PV modules face in the field. For example, in real-world environments, the soiling layer on PV modules builds up and changes over time, dust particles act as abrasives, and factors like dew, humidity, heat, and UV light weaken the ARC.

As PV installations grow, insights from QEERI will help ensure long-term solar power reliability and efficiency in challenging climates. By making solar more cost-effective through reduced abrasion and optimized maintenance, we can accelerate the shift to renewable energy, protecting the environment and natural resources for future generations.