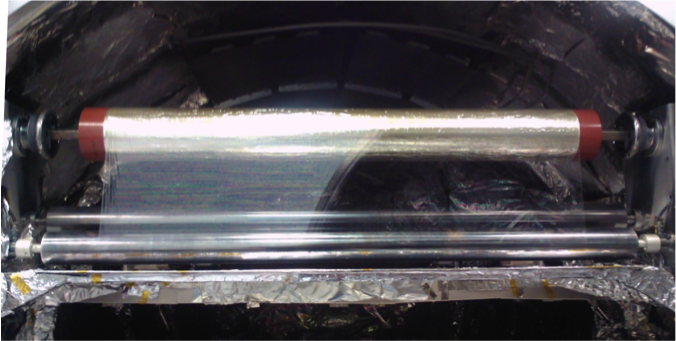

Our unique roll-to-roll coating process was developed in-house for Electron Beam, Jori Source and Ion Assisted Deposition (IAD) of metallic and dielectric films (all processes scalable).

1.8m and 5m chambers accommodate a variety of applications, with deposition on film up to 1000m x 1.5m wide and a great deal of experience handling sub-10 µm films.

Substrates move across four banks of e-beam guns, allowing up to four discrete layers per pass, and PID programmed rate monitoring allows for precise thickness deposition.

Capability to process roll to roll film in a Rewinder cleanroom room (ISO class 5).