Surface Optics was awarded a Phase II NAVAIR Small Business Innovation Research (SBIR) contract to develop antireflection coatings for aerodynamic missile domes and will present this new optical coating technology at the Navy Forum for SBIR/STTR Transition (FST), March 17-18. Hosted by Naval Air Systems Command (NAVAIR), this event connects SBIR/STTR-funded technologies with government acquisition and technical personnel, large prime contractors, system integrators, and other potential transition partners.

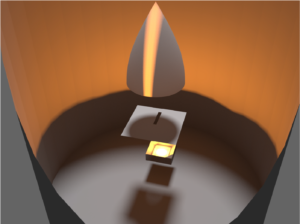

Future high-speed missiles will use aerodynamic infrared (IR) seeker domes, instead of a hemispheric dome, to reduce drag, increase range or speed, and increase the seeker’s field of regard. These aerodynamic domes require an antireflection coating to reduce unwanted reflections that create stray light. The unique structure of the domes creates a coating challenge for traditional line of sight physical vapor deposition (PVD) processes. Surface Optics has developed an improved deposition process to apply view-angle optimized IR coatings on the inside of optical ceramic missile domes, combined with IR imaging metrology to measure coating performance.

“During Phase I, we demonstrated a new approach for the application of multilayer optical antireflection (AR) coatings to the interior surface of the domes using an adaptive mask between the PVD source and dome substrate,” said Sam Dummer, Principal Investigator on the SBIR at Surface Optics. “This approach enables controlled and predictable deposition of AR coatings with controlled thickness profiles. We’re excited in Phase II to build out an automated PVD process fixture that will support AR coating deposition for dome geometries.”

Beyond missile domes, this process is readily adaptable to other applications. It uses proven materials and optical design technology that can transition directly to high-rate production. Commercial applications include medical-lighting systems that use hot mirrors, cold mirrors, and ultraviolet-blocking filters that need to withstand high temperature and high ultraviolet flux. Ball lenses for fiber-optic interconnects used in the telecommunications industry and products such as solar reflectors, infrared- and ultraviolet-curing filters, optical-projection systems, and satellite and space-based optical systems subjected to high thermal loads.

Surface Optics has over 30 years of demonstrated expertise in thin-film design, optical coating fabrication, and characterization. Optical coatings by the Surface Optics Coatings Lab are on the primary mirror of NASA’s Kepler Space Telescope, the SEIS seismic module of the NASA/JPL Mars Insight Lander, as well as antenna and other components of commercial communication satellites.

Read more about our AR Coatings for Aerodynamic Missile Domes and other Complex Surfaces