The relevance of hyperspectral imaging research is growing rapidly, fueled by its increasing viability in real-world and industrial applications. Advances in optics, image processing, data compression, and computing are accelerating this shift—today’s research is laying the foundation for tomorrow’s commercial solutions.

Considering a Hyperspectral Camera?

This blog covers:

- How hyperspectral cameras work

- Typical price ranges (hyperspectral vs. multispectral)

- Cost differences between full systems and standalone cameras

- Smart budgeting strategies to maximize value

What is Hyperspectral Imaging?

Hyperspectral imaging analyzes the light that has been diffusely reflected off the surface of materials. This light may come from ambient illumination (like sunlight) or active sources such as halogen, xenon, or LED lamps. As light interacts with a material, it reflects in a way that is uniquely influenced by the material’s composition, producing a spectral signature that can be captured and analyzed.

This rich spectral information enables the detection and identification of materials, the analysis of subtle changes, and the extraction of chemical or structural details. Examples of hyperspectral imaging applications include:

- Differentiating healthy from diseased crops

- Detecting counterfeit materials or contaminants

- Analyzing surface coatings and thin films

- Classifying minerals or identifying corrosion

- Powering AI-driven inspection or remote sensing workflows

How do Hyperspectral Cameras Work?

Hyperspectral imaging systems operate by combining optics, dispersive elements (like gratings or prisms), and sensitive detectors to separate and record light across many narrow wavelength bands.

- Light from the scene enters the camera lens, which focuses it onto a slit or entrance window.

- A dispersive element, such as a diffraction grating or a prism, spreads light into its constituent wavelengths.

- This spectrally separated light is projected onto a detector array (such as a sCMOS or InGaAs sensor).

- The scene is scanned either by moving the camera — using an external scanning stage, UAV, or an internal mechanism (as in Surface Optics’ SOC710 Series) — or by keeping the camera stationary while the target materials move, such as on a conveyor belt. This process builds a full 2D spatial image with a complete spectrum captured at every pixel.

- A processing unit or onboard software reconstructs the data into a hyperspectral cube — a stack of images, one for each wavelength — and may apply classification, segmentation, or AI algorithms to extract insights.

Hyperspectral Camera Pricing

The image sensor defines the spectral range a hyperspectral system can measure, making it a key factor in both performance and cost. Silicon-based sensors cover 400–1100 nm and are more affordable, while InGaAs sensors—required for shortwave infrared (900–1700+ nm)—significantly increase system cost due to their specialized materials and manufacturing. Longer wavelengths open up advanced material detection capabilities—but at a premium. These ranges are meant to help you get a feel for typical pricing:

Hyperspectral vs. Multispectral

- Multispectral imaging systems typically capture data in fewer, broader bands—anywhere from 3 to 20 discrete wavelengths. These systems are lower in cost, faster in acquisition, and easier to process. They’re well-suited for applications like vegetation health monitoring, industrial sorting, or basic classification tasks where coarse spectral information is sufficient.

- Hyperspectral imaging captures hundreds of contiguous narrow bands, enabling much finer spectral discrimination. This is essential for applications such as detecting trace chemical differences, identifying subtle material changes, or performing quantitative analysis like spectral unmixing or classification based on known spectral libraries.

At the research stage, hyperspectral cameras with higher spectral resolution are ideal for identifying and establishing the spectral bands of interest. When it comes to hyperspectral imaging, the spectral bands of interest are highly application-specific—what matters for one material or target may be irrelevant for another. The key wavelengths used to detect bruising in apples, for example, are not the same as those needed to assess ripeness in oranges or moisture content in grains. However, in some fields like agriculture, certain spectral bands—such as the red edge—are already well-established for assessing plant health, allowing researchers and practitioners to use lower-cost multispectral cameras that target these known wavelengths.

Multispectral Camera Pricing

| Category | Typical Price Range (USD) | Description |

| Entry-Level Multispectral | $1,500 – $5,000 | Low-resolution, fixed-band cameras (e.g., 5–6 bands); often for education or DIY UAVs |

| Industrial / Scientific | $7,500 – $16,000 | Higher precision and spatial resolution, more customizable; up to ~20 bands |

| Custom/High-End Systems | $25,000+ | Application-specific designs, video-rate processing |

While spectral range and spectral resolution largely determine the baseline cost of a hyperspectral camera, frame rate, sensitivity, and spatial resolution are also key performance factors that significantly influence the final price. For more information check out our related post: Important Specifications to Consider When Evaluating Hyperspectral Imaging Systems.

Hyperspectral Cameras vs. Hyperspectral Imaging Systems

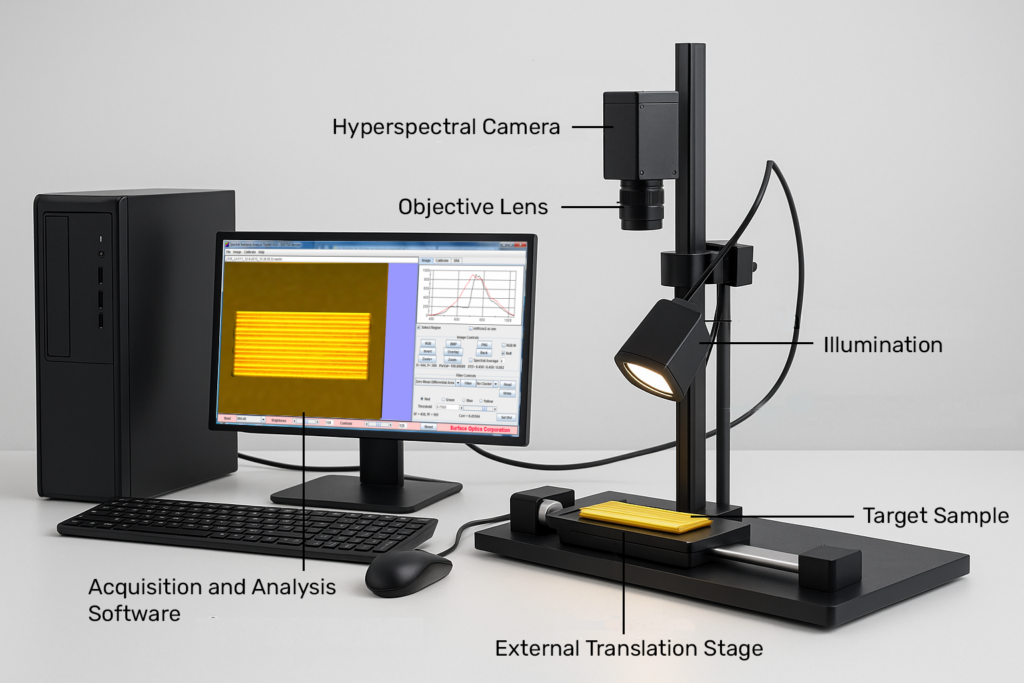

A hyperspectral camera is just one component of a full hyperspectral imaging system. A complete system typically includes:

- Hyperspectral camera

- Lens

- Scanning stage or other platform

- Illumination source

- Calibration reference

- Acquisition and analysis software

- Computer

You’ll need to consider the full system cost—not just the camera—when budgeting for a hyperspectral imaging system for your lab. Equally important is considering your long-term research goals, such as transitioning from lab to field deployments, to avoid costly upgrades down the line.

Consider Long-Term Research Needs

Most pushbroom hyperspectral cameras on the market require an external scanning stage—and in many cases, multiple scanning setups to accommodate different environments. In contrast, the SOC-710 features internal scanning, eliminating the need for proprietary scanning hardware. This allows researchers to add a high-performance hyperspectral camera to their lab that can support a wide range of studies and applications over time.

The SOC-710 is designed for long-term flexibility. It integrates seamlessly with microscopes, lab stands, and field rigs using standard tripods or commercial off-the-shelf mounts—no proprietary accessories needed.

If you’re considering a hyperspectral camera as a long-term asset for your lab, be sure to review the lens options available from the manufacturer. Avoid systems with a fixed lens, as they can limit adaptability across different research setups.

DIY Hyperspectral Cameras

As a hyperspectral camera manufacturer, we fully understand the value of a complete, integrated solution—but we also recognize that sometimes the DIY path just makes more sense, especially when you’re early in your exploration or working with limited funding. Some researchers have successfully built their own hyperspectral imagers using off-the-shelf components, open-source software, and 3D-printed parts. A few resources on DIY hyperspectral cameras:

- A Do-It-Yourself Hyperspectral Imager Brought to Practice with Open-Source Python

- A plug-and-play Hyperspectral Imaging Sensor using low-cost equipment

Opportunities for Cost Savings on Hyperspectral Imaging Systems

Vendors often bundle hyperspectral cameras with necessary accessories like laptops, stages, lighting kits, and calibration panels. These packages can be convenient—and sometimes necessary—especially when making purchases through a grant, where sourcing everything from the hyperspectral camera manufacturer simplifies the procurement process. However, if you’re working outside of that context and already have compatible equipment—or can source it more affordably elsewhere—you can often lower the overall cost by focusing on the core imaging system. Saving opportunities to consider include:

- Laptop/PC: Consult the manufacturer for the minimum performance specifications required to run acquisition and analysis software. For most research applications, your existing workstation likely meets the specs.

- Lighting: Illumination is a critical component for collecting high-quality hyperspectral data. Since hyperspectral cameras capture bands across the visible and invisible ranges of the spectrum, they require a light source that radiates power across a wide range of the electromagnetic spectrum to illuminate the scene being captured. Halogen lights are a component that customers can often source themselves. These lights are widely available from scientific suppliers and even general hardware retailers, making them easy to procure.

- Dark Box / Lab Enclosure: Researchers can easily build a dark box using off-the-shelf components to create a controlled environment for hyperspectral imaging. By using light-blocking materials such as black foam board, blackout fabric, or matte-finish panels, they can construct a light-tight enclosure that prevents ambient light from interfering with spectral measurements. Mounting halogen or LED light sources inside the box ensures consistent, targeted illumination of the sample. This setup improves signal-to-noise ratio and measurement accuracy by eliminating stray light and internal reflections, making it a cost-effective way to achieve reliable, repeatable results in lab-based hyperspectral studies.

- Lenses: We recommend purchasing the lenses offered by your chosen camera manufacturer, as they’ve tested and calibrated their lenses for optimal performance with their systems. Because lenses must be radiometrically calibrated by the manufacturer, it’s wise to consider your long-term needs and, if possible, purchase multiple lenses to cover different fields of view—this helps avoid the downtime and cost of sending the camera back for calibration with a future lens purchase.

A hyperspectral imaging system can be a valuable long-term asset for your research lab. Because applications have varying priorities and technical requirements, pricing can differ widely. Our application scientists are here to help you navigate options.

Want more information? Send us a quick message about your application.